Ergonomics and Radio Buttons

By Bob Colegrove

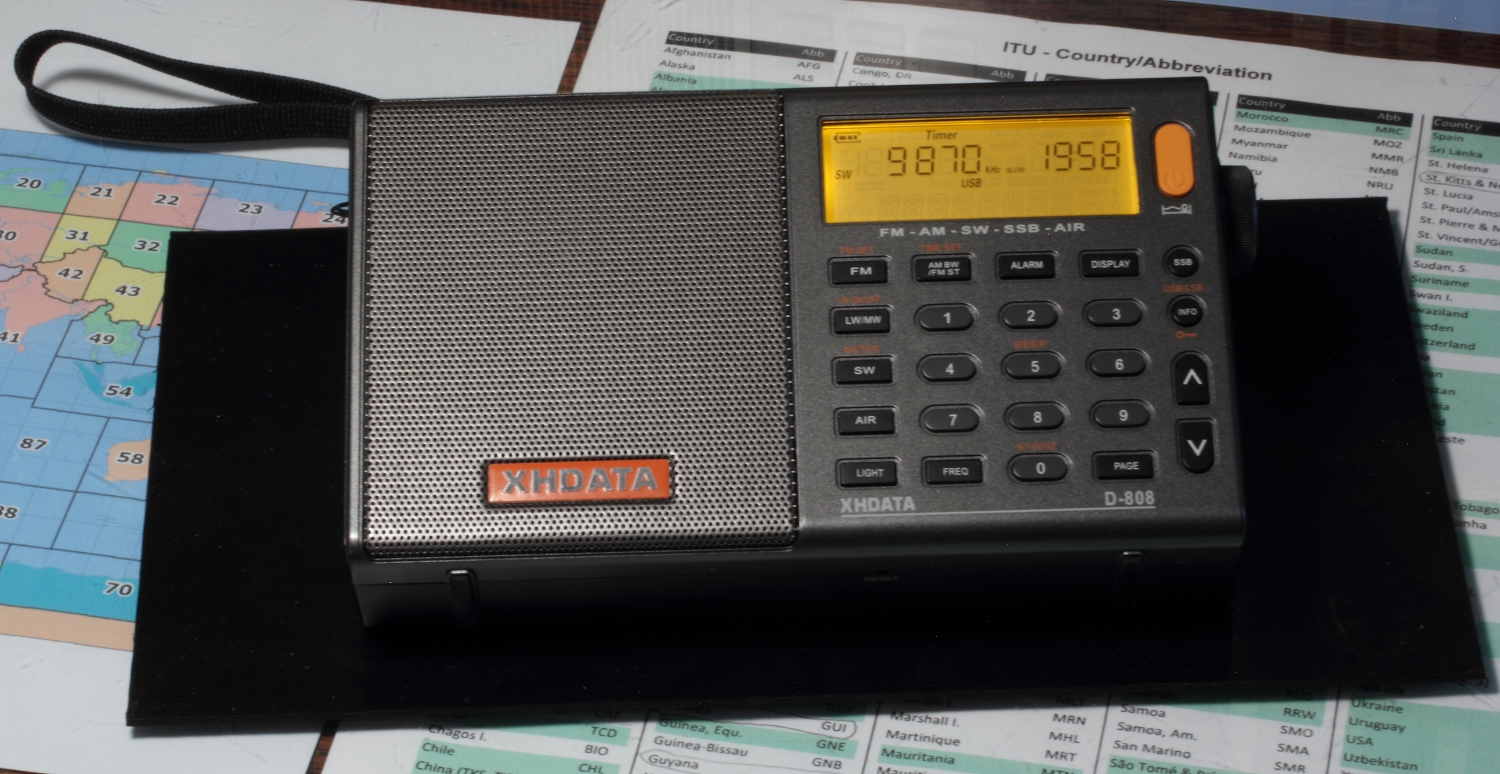

Am I being too picky? Are the buttons on some newer portable radios hard to press? I’ve read many reviews and watched as many videos, but haven’t encountered many complaints about this. Perhaps it’s an age-related affliction.

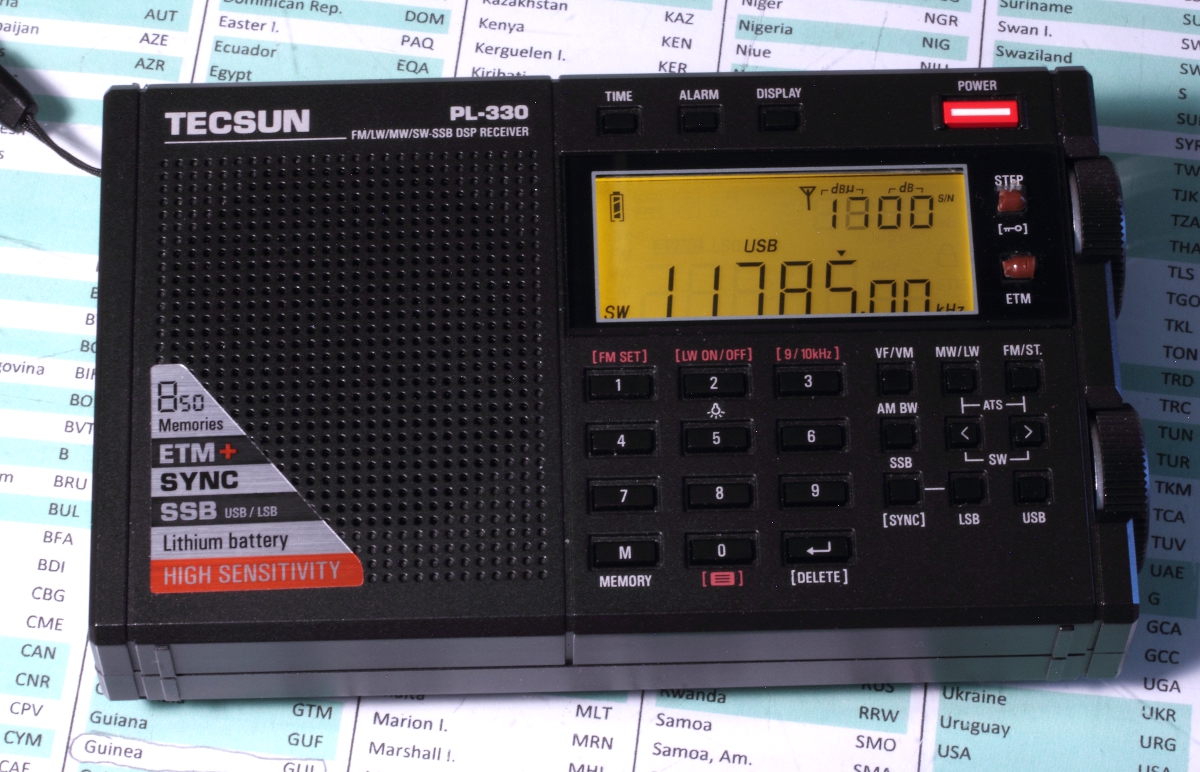

The most succinct description of the problem was expressed in the review of the Tecsun PL-660 way back in the 2012 edition of the WRTH. In referring to the buttons, “All are in our view rather too small for comfort and have breakout forces which are out of all proportion to their size; the combination of this with excessively long travel and weak tactile feedback does not give much pleasure to the user.” The problem has only gotten worse with some newer portable radios.

I see two problems here. First, too much pressure is required; what the WRTH called “breakout force.” Designers may say, “that’s so you won’t accidentally turn the radio on and run down the battery.” Well, I reply, “isn’t that what the ubiquitous lock button is for? They all have one.”

If you’ve ever taken one of these radios apart, you’ve likely seen a pliable membrane between the buttons and the switches or traces on the PC board. This provides some spring action necessary to return the buttons to the upright position. Couldn’t this be thinner or more elastic?

Second, some radios have flat buttons that don’t protrude very far above the case. By the time the fleshy part of your finger bottoms out on the surface of the case, still more pressure and button travel is required to activate the function. Couldn’t the buttons be slightly higher?

The result, if you operate the radio on a desk or table and apply the requisite walnut-cracking pressure on a button, the radio might well rocket off its foundation.

Pads for Portables

A partial solution without violating the integrity of the radio is a stable foundation. In today’s euphemistic world the term counterpoise is use when referring to what we used to simply call an electrical ground. It seems some sort of mechanical counterpoise would be useful to better anchor a portable radio for operation.

Neoprene is a synthetic rubber developed by a DuPont scientist in 1930. It is tougher than natural rubber and relatively impervious to solvents. This stuff is virtually skidproof. There are perhaps other materials suitable for this application, which is simply to get the radio to stand its ground while you operate it. After some thought and experimentation, I bought a 1/16”-thick neoprene pad. A 12” × 12” pad is more than enough. Mine came from https://amzn.to/3XsmQDe [Note Affiliate link supports the SWLing Post]. I cut this into three smaller pads as follows:

7” × 12” for a Sony ICF-2010, which has nice easy-touch buttons and really doesn’t need a pad except to anchor the radio in place.

5” × 9” for a Tecsun PL-990 and many other similar size radios.

3” × 5”, the scrap piece can be used for a C.Crane Skywave, which already has nice raised buttons; a Tecsun PL-330, which needs a pad most of all; and an XHDATA D-220, which doesn’t even have buttons.

There are a couple of alternatives:

- You can leave a large pad uncut to accommodate various sizes of radios; or

- You can cut bits of neoprene and apply them as feet to the bottom rear corners of the radio and bottom of the stand. There might be some difficulty getting them to stay in place or allowing the stand to fully collapse. Some portables already have rubber feet.

It’s probably apparent that neoprene will adhere best to a smooth surface such as glass or Formica. However, I have tested it on a cloth-covered, memory foam chair cushion, and it works just fine. Pressing down the material will make it adhere to a surface even more. I would estimate that a lateral force of at least 10 or 15 pounds is required to make a small radio break loose from three or four points of contact with the material.

Besides holding the radio in place while you operate it, much like a large table radio, neoprene offers the radio some cosmetic protection against abrasion from rough surfaces. However, the material is so sticky it will pick up every bit of dust or dirt. This can somewhat compromise its adherence requiring an occasional rinse in water.

Admittedly, the neoprene pad isn’t going to be very useful while you’re sitting in a beach chair using the radio in the handheld posture. However, in the shack, a suitable pad has a purpose.

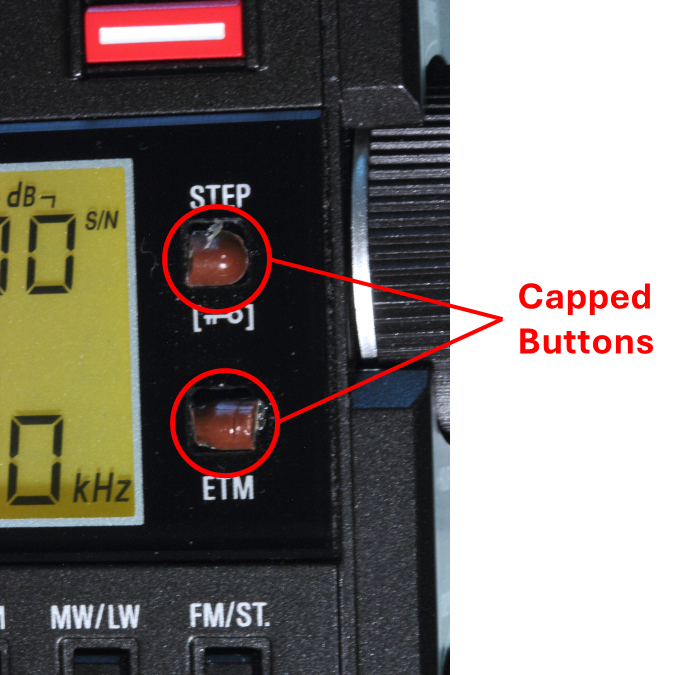

Caps for Buttons

In the case of buttons which are too low, some additional help is desired. On the Tecsun PL-330, I glued plastic caps on top of the STEP and ETM buttons, which raises them about 1/16” and helps considerably. I am still looking for some transparent material to use as caps on the numbered buttons.

Further validated suggestions are solicited.

I have fixed many radios that have broken traces on PC boards due to the force required to operate the switches. The price levels on these radios ranges from an impulse buy sort of item to over $1000 street price. I have to think at this point this is built in obsolescense, they wear out so you have to, in many cases, buy another radio to replace the worn out one. Then you have the carbon buttons many scanners and HT’s have that fail after a while. I must have replaced a couple of hundred keypads on GRE/Whistler made scanners over the years. Some people “clean” them, some have come up with some sort of replacment carbon paint to renew the switch function, but replacing the keypad is the best way to fix them.

I think a long term solution at the manufacturing end would be to use whatever the switches are in even a cheap “chiclet” PC keyboard and just basically eliminate the problem from occurring until the radio is very old. I just recently retired a 10 year old Dell keyboard used 8+ hours a day 5 days a week. The enter and backspace keys began to be intermittent, and once it got to a certain level, it was trash can time.

Remember, TV remotes are almost radios. Xfinity provided new remotes for their cable boxes. They are smaller, the buttons are smaller, and the breakout force required is so great that those with poor hand strength will not be able to reliably press the buttons.

As a radio lover with physical impairments, this topic is a particularly important point of consideration. Thanks for mentioning it, and please continue to do so.

Good advice about the neoprene! I just got a Raddy RF919. One thing I noticed is that the lock button is very poorly labeled. Just to see the markings, I had to use a strong magnifying glass besides my reading glasses.

Darn it, Bob, you’ve done it again: produced another interesting and insightful piece.

To your point, I’ve had an interesting encounter of the “button kind. I was slumped in bed, headphones clamped on, repeatedly pressing the SCAN button on my CCrane SkyWave SSB.

Presently, the Better Half, who was attempting to drift off the sleep, says, “Could you stop that?”

“What?” I said.

“Too much clicky-clicky,” she said.

Point well taken, I later purchased a radio that was mechanically quieter to operate.

I treasure radios that tune smoothly and are mechanically quiet to operate.

Good article . . . I look forward to whatever you write next.

Cheers, Jock

You’re lucky, Jock. I was told to stop snoring, and get a CPAP machine.

I think the older Sony radios probably had the best buttons. Easy to press and no hard clicking sound. But Sony really fell down with the ICF-2010 in the Blue Lettering on a Black Background. My old eyes can barely read them unless I get the lighting just right on the keypad. But even with that, the 2010 is still one of my favorite radios that I use all the time.

The Tecsun PL-880 has a nice key pad. Keys are all raised to the same level and have a solid keypress with a slight click.

I agree with you on the PL-330. The keys are fairly small (of course it is a small radio) and slightly recessed. And the Step and ETM keys are recessed so that they are flush and require me to use a finger nail to operate them. I like your ideal of adding a bump to them.

I have a couple of the ATS-120 radios that do have a touch screen. It’s not capacitance type but pressure type touch, but does work quite well. I just use my fingernail to press the screen. I haven’t really seen any noise from the screen. But I do see that the latest 4.2 Beta software includes a touch screen lock that says it should reduce the digital screen noise. I haven’t loaded the beta software yet, so not sure what effect it really has.

73

Bill WD9EQD

Smithville, NJ

I am surprised that these manufacturers haven’t gone to touch screens. You only need a real momentary action switch initiate the lighting of the screen on demand with a time out for the display to go out. Many of these receivers already contain a microprocessor which could be used to display the ‘buttons’ and detect the location of any finger touching the screen. It would be difficult with a wet screen if used outside.

This would not only make the buttons bigger, more controls can be included particularly on physically small receivers. The only disadvantage is submenus.

One of the reasons you don’t see a lot of touch screens on sub $200 SW portables is because it can be difficult to sort out internally-generated noise once a touch screen has been added.

i agree, one smartphone style touchscreen has to be cheaper than 20 to 30 buttons, plus then they could use the smartphone style screen to show spectrum and waterfall like an SDR