Many thanks to SWLing Post contributor and RX antenna guru, Grayhat, for another excellent guest post focusing on compact, low-profile urban antennas:

Many thanks to SWLing Post contributor and RX antenna guru, Grayhat, for another excellent guest post focusing on compact, low-profile urban antennas:

A linear loaded dipole for the SWL

by Grayhat

What follows is the description of an antenna which may allow to obtain good performances even in limited space, the antenna which I’m about to describe is a “linearl loaded dipole”(LLD) which some call the “cobra” antenna due to the “snaking” of its wires

The arms of the antenna are built using 3-conductors wire (which may be flat or round) and the 3 conductors are connected this way:

That is, connected “in series”, this means that, the electrical length of the antenna will be three times its physical one; this does NOT mean that the antenna will perform like a single wire of the same (total) length, yet it allows to “virtually” make it longer, which in turn gives it good performance even with relatively short sizes. Plus, the distributed inductance/capacitance between the wires not only gives it a number of “sub” resonance points, but also helps keeping the noise down (in my experience below the noise you’d expect from a regular dipole). At the same time it offers better performances than what one may expect from a “coil loaded” dipole. Plus, building it is easy and cheap and the antenna will fit into even (relatively) limited spaces (a balcony, a small yard and so on…).

Interested–? If so, read on and let me start by showing my (short – 9mt total) LLD installed on a balcony:

Here it is in all its “glory”–well, not exactly–I fiddled with it lately since I’m considering some mods so the tape isn’t correctly stuck and it has been raised and lowered quite some times, but in any case that’s it.

Bill of Materials

Here’s what you’ll need to build it (the links are just indicative, you may pick different stuff or buy it locally or elsewhere).

- Some length of 3-conductors electrical wire which will fit your available space (pick it a bit longer to stay on the safe side), it may be flat or round, in my case I used the round type since it was easily available and cheap: https://amzn.to/3g2eZX3

- A NooElec V2 9:1 BalUn–or, if you prefer you may try winding your own and trying other ratios. I tested some homebuilt 1:1, 1:4 and 1:6 and found that the tiny and cheap NooElec was the best fitting one): https://amzn.to/3fNnvce

- A small weatherproof box to host the BalUn: https://amzn.to/33vjZy3

- A center support which may be bought or built. In the latter case, a piece of PCV pipe with some holes to hold the wires should suffice. In my case I picked this one (can’t find it on amazon.com outside of Italy): https://www.amazon.it/gp/product/B07NKCYT5Z

- A pair of SMA to BNC adapters: https://amzn.to/37krHwj

- A run of RG-58 coax with BNC connectors: https://amzn.to/2JckHcR

Plus some additional bits and pieces like some rope to hang the antenna, some nylon cable ties, a bit of insulated wire, duct tape and some tools. Notice that the above list can be shortened if you already have some of the needed stuff and this, in turn will lower (the already low) cost of the antenna.

Putting the pieces together

Ok, let’s move on to the build phase. The first thing to do will be measuring your available space to find out how much wire we’ll be able to put on the air; in doing so, consider that (as in my case), the antenna could be mounted in “inverted Vee” configuration which will allow to fit the antenna even in limited space.

In any case, after measuring the available space, let’s subtract at least 1m (50cm at each end) to avoid placing the antenna ends too near to the supports. Also, if in “inverted Vee” config, we’ll need to subtract another 50cm to keep the feedpoint (center/box) away from the central support.

Once we’ve measured, we may start by cutting two equal lengths of 3-conductor wire. Next, we’ll remove a bit of the external sleeve to expose the three conductors and then we’ll remove the insulator from the ends of the three exposed wire (and repeat this at the other end of the cable and for both arms).

The resulting ends of each arm should look somewhat like in the example image below

Now we’ll need to connect the wires in series. We’ll pick one of the cables which will be the two arms of our antenna and, assuming we have the same colors as in the above image, we’ll connect the green and white together at one end and the black and green together at the other end. Repeat the same operation for the second arm and the cables will be ready.

Now, to have a reference, let’s assume that the ends of each arm with the black “free” (not connected) wire will go to the center of our dipole.

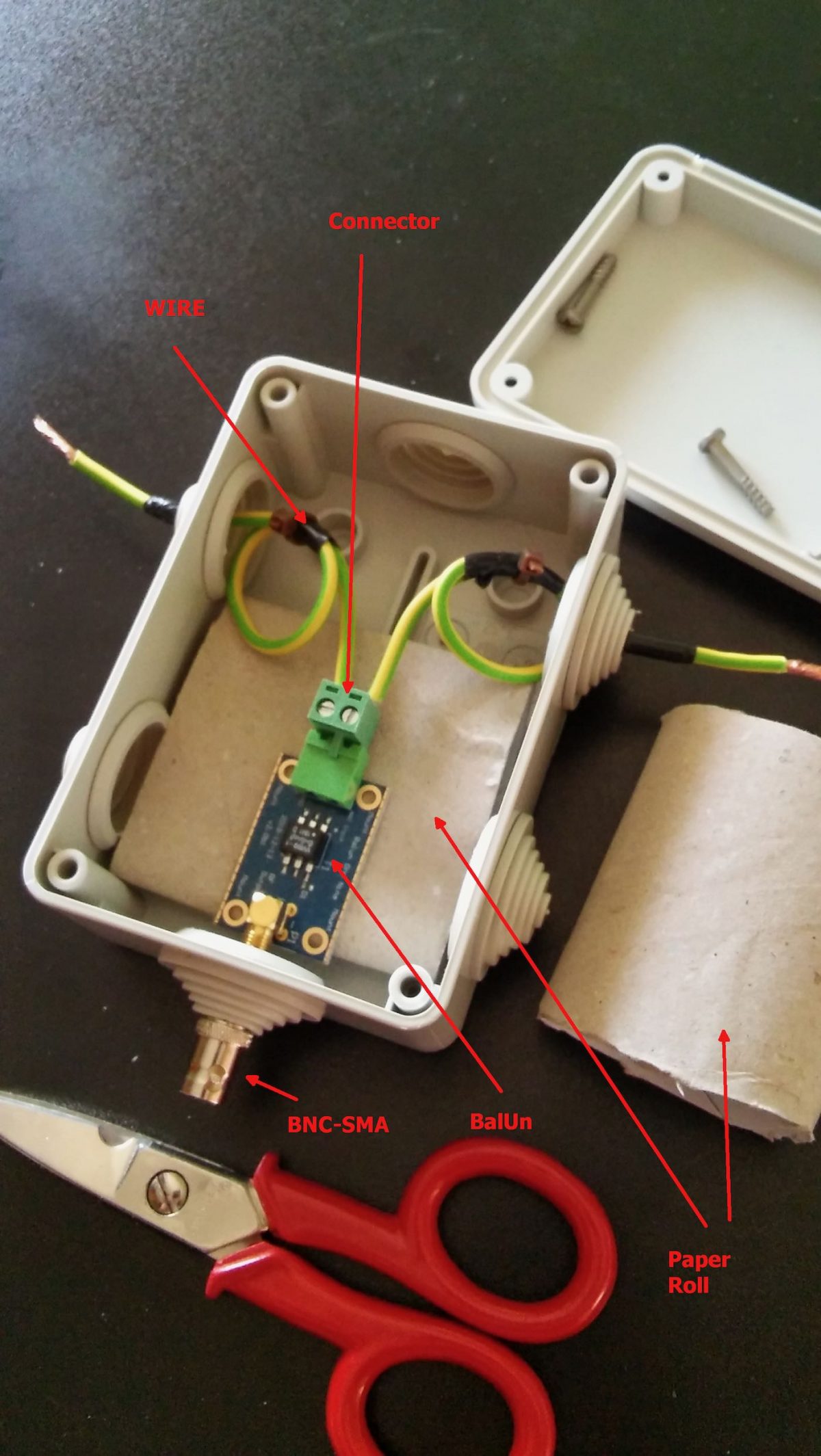

Leave the two arms alone for a moment, and let’s install the balun inside the waterproof box. To do so, we’ll start by cutting a (small) hole through the single rubber cap found at one side of the box, then insert the cap reversed, so that it will protrude to the inside of the box and not to the outside. Slide the balun SMA connector through the hole so that it will protrude outside the box.

Now use a marker to mark the balun position and remove the balun from the box. Pick a piece of wood/plastic or other insulating material, cut it to size (refer to marking and to balun size) and drill four holes matching the one found on the balun board. Slide four screws through the holes and lock them with nuts, the screws should be long enough to extrude for some mm. Now insert the balun in the screws using the holes present on the balun board and lock it with nuts (be gentle to avoid damaging the balun). At this point, add some “superglue” to the bottom of the support we just built, slide the balun SMA connector through the rubber cap hole we already practiced, and glue the support to the bottom of the waterproof box. Wait for the glue to dry.

Just to give you a better idea, see the photo above. That’s a photo of the early assembly of my balun. Later on, I rebuilt it as described above (but took no pics!), the image should help you understanding how it’s seated inside the box–by the way in our case it will be locked by the screws to the plastic support we glued to the box.

While waiting for the glue to dry, we may work on the dipole centerpiece.

If you bought one like I did, connecting the arm “black” (see above) wires should be pretty straightforward. If instead you choose to use a PVC pipe you’ll have to drill some holes to pass and lock the wire so that the strain will be supported by the pipe and not by the wire going to the balun box. In either case, connect a pair of short runs of insulated wire to the end (black) wire coming from each end. Those wires should be long enough to reach the balun wire terminal block inside the box.

Assuming the glue dried, it’s time to complete the feedpoint connection.

Bring the two wires coming from the centerpoint inside the waterproof box. Pick one of the wire terminal blocks which came with the balun (the “L” shaped one should be a good choice) and connect the wires to it. Then, slide the block in place until it locks firmly. After doing so, close the box and screw the SMA-BNC adapter onto the SMA connector coming from the balun. Our centerpiece and arms will now be ready, and will be time to put our antenna up!

I’ll skip the instructions about holding the arm ends and the centerpiece up, since I believe it should be pretty straightforward. Just ensure to put the antenna as high as possible and, if you have room make the arms as long as possible. In my case, due to my (self-imposed) limitations, the antenna was installed on a balcony. The arms have a length of about 3.5m each and the feedpoint (in the image above) sits at about 9m off the ground.

The more acute readers probably noticed those “blobs” on the coax, they are snap-on ferrite chokes I added to the coax (there are more of them at the rx end) to help tame common mode noise. I omitted them from the “BoM” since they may be added later on.

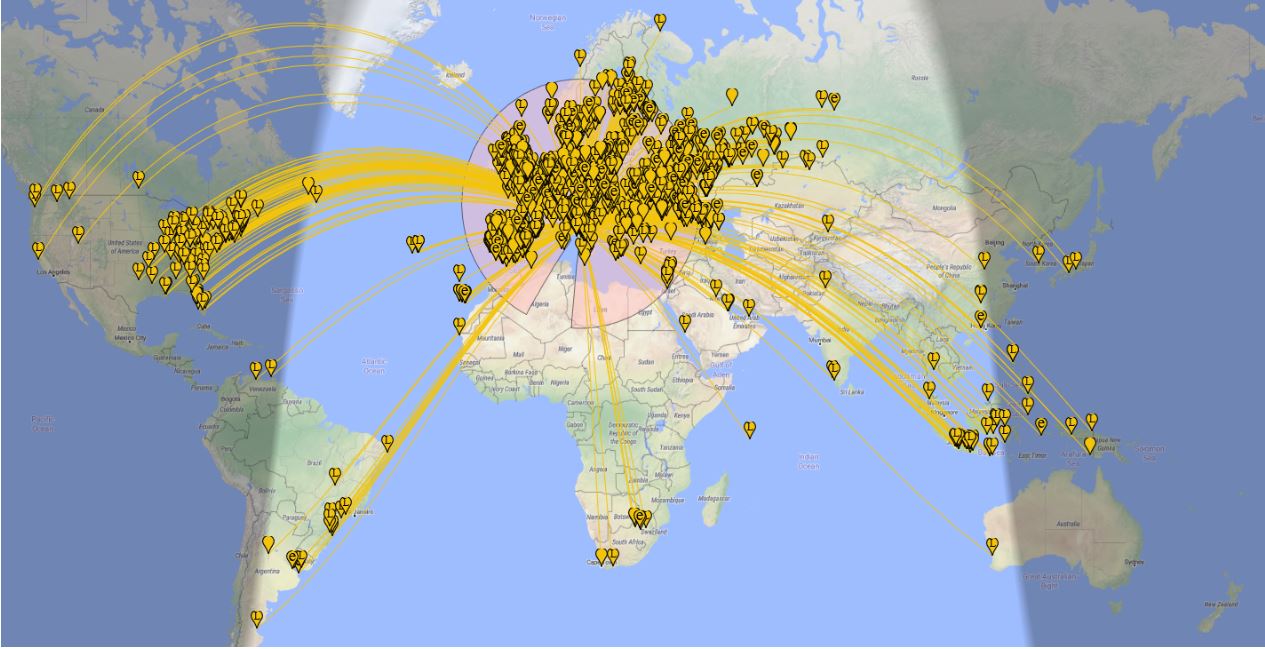

Anyhow, now that you have your LLD up it will be time to give it a test! In my case, I decided to start by running an FT8 session to see what the antenna could pick up during 8 hours, and the result, on the 20 meters band, is shown on the following map (click to enlarge):

Later, that same antenna allowed me to pick up signals from the Neumayer station in Antarctica–not bad, I think!

Some final notes

While running my “balcony experiment”, I built and tested several antennas, including a vanilla “randomwire”, a dipole, and a T2FD.

Compared to those, the LLD offers much less noise and better reception on a wide frequency range. By the way, it won’t perform miracles, but it’s serving me well on the LW band, on most ham bands, and even up to the Aircraft bands–indeed, was able to pick up several conversations between aircraft and ground air traffic control.

All I can suggest is that given a linear-loaded dipole is so simple, quite cheap, and may fit many locations, why don’t you give it a spin–? 🙂

Thanks for taking the time to explain your antenna project, I love it.

What did you do to close-insulate the extremes (arms) of the antenna? assuming there is one wire free and two attached at the very end fo each arm, as in your first picture.

I’m new on this.

Also, I have a Tecsun PL-330, so to connect the antenna with coaxial I’ll need a converter from coaxial to 3.5mm jack, right?

Thanks!

When putting the wire together, what did you do with the white end of the wire that’s unattached?

Thank you so much for publishing this article. I have built one and I must say that of all the solutions that I have tried on my balcony, this one has given me the best results by far. Mine is only 7.5 meters mounted up against by glass balcony railing and I get great results above 5 MHz or so.

Thanks so much for a great idea!

Implemented one for myself in 7 m wire length end-to-end. It did not bring anything out that I cannot receive with integrated whip of my Tecsun PL-990. It performed a very tiny bit better in 13-17 MHz range with a bit less noise. But noise might be due to the fact that I was sitting with the radio closer to some PSUs.

In fact I tried quite a lot of antennas, but none of them significantly outperformed Tecsun’s own whip. I suppose, it’s time to try out some resonant antenna, just not yet sure for what exactly 🙂 Even my Bonito Megaloop FX with aluminum 90 cm tube loop does not highly impress me…

Great article. Nice to see someone carrying out some ‘real world’ experimentation. Coincidently, I have been messing around visually discreet, Linear Loaded VHF/UHF vertical antennas for wide-band receiving purposes – I was amazed at the wide bandwidth and performance obtained with my very simple constructions.

Keep up the good work.

First of all, thank you all for the comments, then; I’m not sure if using thin conductors like the ones in a computer ribbon cable will work well for this antenna, the wires will be too near and I suspect that may impact on performance

That said, in case someone wants to try running a simulation on the antenna, the text below is a 4NEC2 model which will allow to play with the various parameters (wire diameters and spacing, arm lengths, antenna height) to see the effect they have on the pattern

CM =============================================================

CM Linear Loaded Horizontal Dipole (also known as “cobra” dipole

CM to see the structure, change the values from spac and cent to

CM 0.5 and reload the model; restore the values to original when

CM running simulations on the antenna model

CM =============================================================

CE

SY hght=9 ‘ height from ground

SY arms=5 ‘ arm length

SY wire=0.0005 ‘ 3-conductor wire radius

SY spac=0.00105 ‘ 3-conductor wires spacing

SY cent=0.05 ‘ center spacing

SY freq=14.175 ‘ test frequency

‘ first wires

GW 1 50 0 0 hght 0 arms hght wire

GW 2 50 0 0 hght 0 -arms hght wire

‘ second wires (spaced at center)

GW 3 50 0 cent hght-(1*spac) 0 arms hght-(1*spac) wire

GW 4 50 0 -cent hght-(1*spac) 0 -arms hght-(1*spac) wire

‘ third wires (spaced at center)

GW 5 50 0 cent hght-(2*spac) 0 arms hght-(2*spac) wire

GW 6 50 0 -cent hght-(2*spac) 0 -arms hght-(2*spac) wire

‘ 1st to 2nd vertical junctions

GW 7 10 0 arms hght 0 arms hght-(1*spac) wire

GW 8 10 0 -arms hght 0 -arms hght-(1*spac) wire

‘ 2nd to 3rd vertical junctions

GW 9 10 0 cent hght-(1*spac) 0 spac hght-(2*spac) wire

GW 10 10 0 -cent hght-(1*spac) 0 -spac hght-(2*spac) wire

‘ ground

GE -1

GN 2 0 0 0 13 0.005

‘ short wire junctions (load)

LD 5 7 0 0 58000000

LD 5 8 0 0 58000000

LD 5 9 0 0 58000000

LD 5 10 0 0 58000000

‘ feedpoint

EK

EX 0 1 1 0 1. 0 0

‘ initial frequency

FR 0 0 0 0 freq 0

EN

As a devoted antenna experimenter I say great article. I’ve used computer ribbon cable to build portable antennas such as the NorCal Doublet, and will build an LLD using the same materials.

Steve, KZ4TN

Thanks for the article, the antenna would fit nicely in my hedge row. I have a lot of 3 conductor electrical wire and RG6 coax so the cost will be minimal.

Having built a number of surprisingly well working doublets and loops using the NooElec balun myself, this is a great idea to reduce the required space.

I hope you don’t mind one note though (learned that the hard way): Using RG-58 for a feedline is not recommendable in many cases, even more when the output voltage of the antenna is expected to be low. Imagine the coax is generally running through the noise “halo” of the building and possibly through spots where noise sources are close (e.g. in the shack), a shield effectiveness of typically 45dB for cheap RG-58 can ruin any noise cancelling and quiet install location finding efforts put into an antenna. The more noise there is in the house and the shack, the more important it will be to use double-/foil-shielded coax of good quality. My H100 lines were all more expensive than the antennas at the other end, but (particularly given their length and the noise level in my shack) that was a good investment. 🙂

13dka, first of all, thank you for your comment; that said

You’re right, a better coax could help a bit, but considering that in my case the RX is pretty near and the coax run is quite short, the RG-58 is serving me well and, for sure much better than the thin coax shipped with a number of “chinese” whips and loops 🙂

Also consider that the idea is to show how to build an “LLD” on a shoestring, then, by the way there’s always room for improvement, and if one wants, nothing/nobody forbids him from using a run of “Messi & Paoloni” high quality, low loss coax 😀

HI Andrew,

I understood that this is a least-cost suggestion and there are sure still situations where the shielding doesn’t matter that much. However, coax is likely the most overlooked and neglected intrusion vector for noise and the QRM levels in (probably all, but for sure in Europe) densely populated areas have increased dramatically, and there is hardly any household that doesn’t have any intense (and wideband) noise sources. So I always feel an urge to increase awareness about badly shielded coax when someone mentions “RG-58”. 🙂

Agreed on the RG58. For receive antennas you can’t beat the price of good, quad-shield RG6 (75ohm TV coax). A friend did some testing with some Southwire quad-shield, the only thing that he had that was lower-loss was LMR400. Buy a 500-foot spool and you won’t regret it for antenna projects. The main issue is terminating it, so to make things easy, I just use good TV crimp-on F-connectors and use an adapter from that to whatever I need.

It is not my only feedline type in use, but I do use RG-6 quite extensively, especially for receiving antennas. It is very affordable, easily obtained at many “big box” hardware stores, and well suited for low loss at HF and lower frequencies.

With the proviso that, at least in many places outside the US, hardware store “RG-6” is RG-6 in dimensions only, and is cheap CCS construction. Which is fine at VHF frequencies, and depending on cladding quality/thickness *might* be OK above 10MHz or so – or, more likely, 20~30MHz for the cheap hardware store stuff – but rapidly gets very lossy below that.