Vintage tube radios will likely survive an EMP, but how do you power them without mains electricity?

Here’s a common question I receive from SWLing Post readers:

“Where can I have my vintage valve/tube radio repaired? Can you recommend a good repair service?”

The answer isn’t always a simple one, especially for those living in rural or remote parts of the world.

Go local

The short answer is: try to find a local repair service.

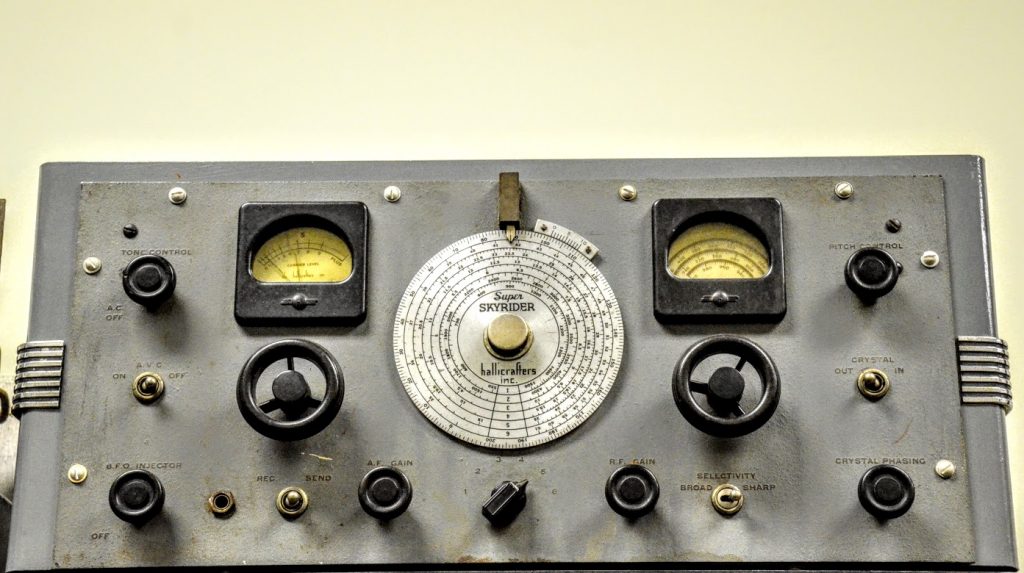

Unlike modern solid state radios, “boat anchors” (metal chassis vintage radios) are heavy and very pricey to ship.

Some repair services and retailers won’t even consider shipping vintage metal chassis radios because of the likelihood of damage or a tube or other component loosening during transit resulting in a DOA (Dead On Arrival) situation. They insist on in-store or local pickup/delivery.

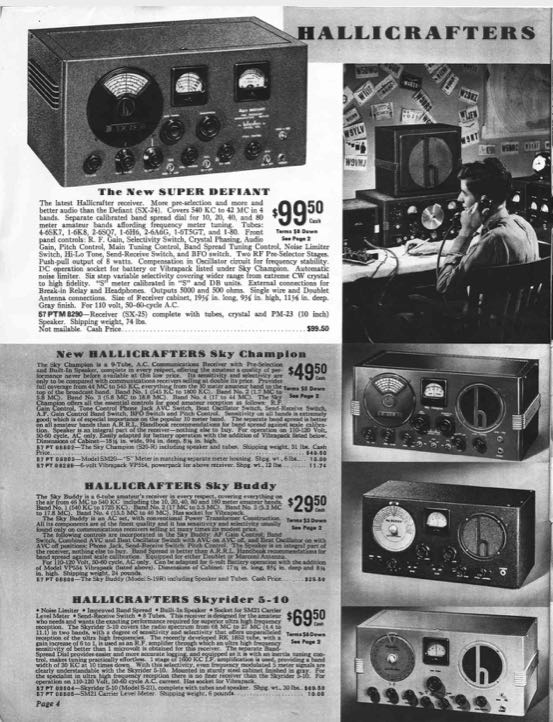

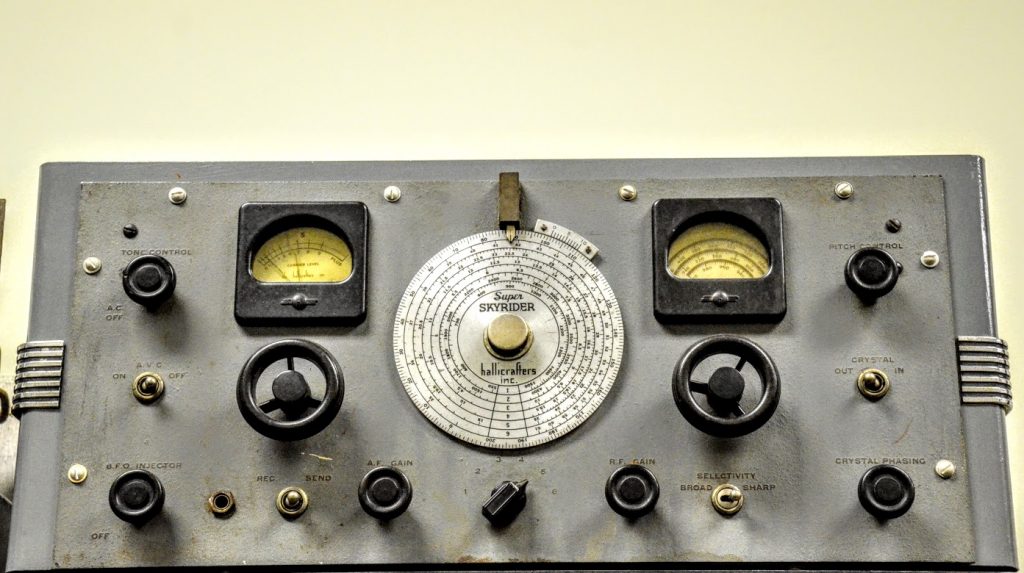

Last year at the Dayton Hamvention I was speaking with an acquaintance who restores and repairs vintage tube radios–he specializes in WWII and Cold War era boat anchors (Collins, Signal Corps, Hallicrafters, National HRO, etc.). Although he makes a tidy profit from doing repairs, it’s most certainly a labor of love and not the most profitable use of his time. He told me that he recently stopped accepting any repairs other than those delivered and picked up locally.

He told me he took great care in packing equipment after repairs had been made–he’d secure all components so that they couldn’t budge during shipment and would either double box or use industrial strength cartons. Being so diligent, his return shipments almost always arrived unscathed, but customers would complain about the shipping costs. He could, of course, skimp on packaging, but then risk his repair work being undermined by rough handling. He was never willing to compromise on shipping and I certainly don’t blame him.

So again, due to the complexities of shipping heavy gear, I always recommend trying to find someone local to do your “boat anchor” repair work first.

Where can you find a local repair shop? If you belong to or know of a local ham radio club, stop by a meeting and ask around. If there’s a vintage radio repair technician in town, someone in the club can likely connect you.

Shipping boat anchors

With that said, there are some excellent repair technicians out there who will take work via parcel shipments, but be prepared to pay upwards of $50-150 each way each way (depending, of course on the radio size and weight).

Lighter tube radios are easier and cheaper to ship, but should still be packed carefully. Bakelite radios, for example, are lightweight but incredibly fragile.

In short: if you ship your vintage radio, pack meticulously and confirm that your repair person will do the same.

And where do you find repair services? I point readers to radio repair service reviews on eHam.net. You might also search the QRZ.com forums or even post a question.

Let’s be clear: some radios are worth the shipping costs!

Let’s be clear: some radios are worth the shipping costs!

I am fortunate in that I do have a local friend and mentor Charlie (W4MEC) who repairs tube gear. Better yet, Charlie is willing to teach me how to do repairs and alignments myself. This, I would argue, is the best of both worlds!

A Note of Caution: When it comes to repairing tube/valve gear, I believe you should always learn the ropes with an experienced technician. Unlike battery-powered solid state devices, tube gear is mostly high voltage. If you don’t know what you’re doing inside the chassis of a tube radio, you could be severely shocked or even electrocuted. No radio is worth that price.

Who do you recommend?

If you have any advice about repairing boat anchors and other vintage electronics, please comment! Also, if you can recommend a repair service, please share details.