Many thanks to SWLing Post contributor Dale (W4OP), who shares the following guest post:

Going Old School: The Lowe HF-150

by Dale (W4OP)

Lowe Electronics of Great Britain introduced their first shortwave receiver, designed by Jon Thorpe, in 1987: the model HF-125. The HF-125 was a 30 kHz to 30 MHz compact receiver with three filter bandwidths and AM/SSB/CW detection. As with all of the Lowe receivers, the HF-125 combined excellent build quality with no-nonsense operation. Options included a whip amplifier, keypad for direct frequency entry, and an AM synchronous detector. The diminutive receiver was an instant hit and was manufactured until 1989, when it was replaced by the HF-225. While slightly larger (9” x 10” x 4”), the HF-225 included the built-in whip amplifier, but AM sync was still an option. The HF-225 had a long run from 1989 to 1997. The front panels of the HF-125 and HF-225 were very similar and easy to operate.

There was also a “professional” version of the HF-225 called the HF-235. It was considerably longer than the HF-225 with rack handles, a front-facing speaker, keypad, and, I believe, a built-in 110/220 VAC power supply.

In 1991, Lowe, under the design of Thorpe, introduced the remarkable HF-150, the subject of this paper. Gone were the painted and bent metal enclosures, replaced by a beautiful anodized, extruded aluminum cabinet almost 1/8” thick. The HF-150 was also smaller (7.3” x 3” x 6.3”) and lighter. While the keypad was still an option, the HF-150 now contained built-in batteries and a built-in charger.* When the HF-150 came out, rechargeable batteries were NiCad, and typical capacity was 1000mAh. The HF-150 typically draws 250mA, so the NiCads in the HF-150 might give you 4 hours of run time. Today, we have NiMH batteries that have a higher energy density than NiCad cells, and I routinely see 2800mAh. That means around 10–11 hours of run time on a single charge.

In the HF-150, the whip preamp is built in, not an option. The whip and its preamp are equivalent to the short active antennas we often see in use today. This is a great feature and results in very good sensitivity from a very short antenna. A three-position slide switch on the rear panel allows for running from the active whip, a conventional antenna like a dipole, or a random wire. The slide switch also allows for introducing a -20dB attenuator to prevent overload. This was a condition often seen in Europe back in the day when there were so many high-power shortwave stations.

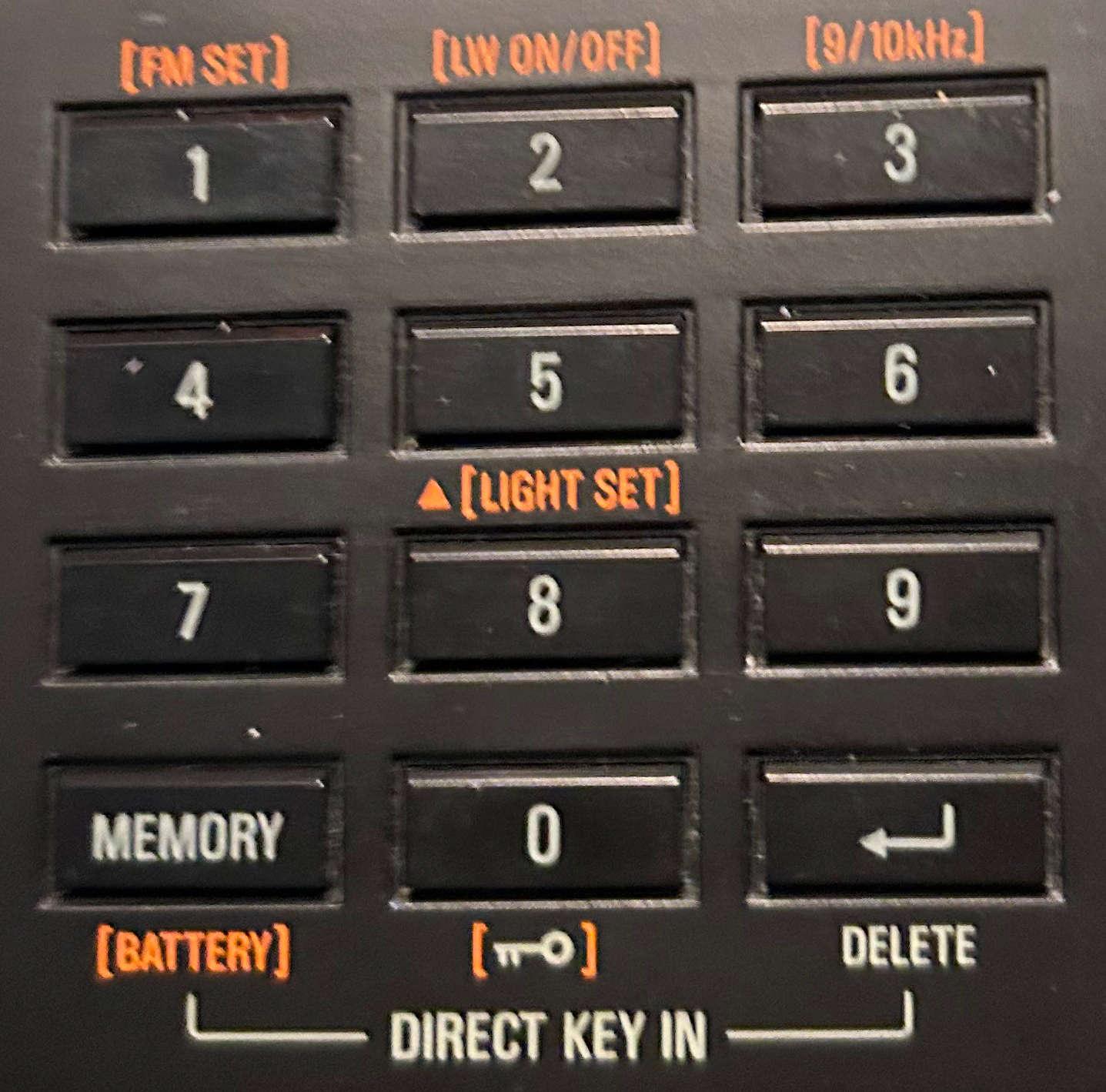

Also on the rear panel is a socket for the optional keypad, a socket for an external speaker, and a socket for a recorder output. The two battery boxes house a total of 8 AA batteries.

The front panel could not be simpler or more elegant in its design. There are only 2 knobs—AF Gain and Main Tuning—and three momentary push buttons. The use of these three buttons is the magic in this receiver.

The leftmost push button controls 60 memories. The main tuning knob cycles through the memories at about 25 memories per knob revolution.

While in the memory mode, the center and right-hand push buttons allow for recalling the current memory or storing the current frequency, respectively.

The rightmost push button changes the tuning speed to 100 kHz/step and allows for very fast QSYing through the entire receiver range. The frequency display in fast mode shows only the MHz and 100 kHz positions.

Press Fast again, and the display reverts back to displaying the 1 kHz least significant digit. The normal tuning rate depends upon the mode. In SSB, the steps are 8 Hz (1.6 kHz/revolution). Normal AM and AM Narrow are 60 Hz (12 kHz per revolution). There are four AM sync modes:

- Double sideband sync 8Hz steps 1.6KHz/rev 7KHz filter

- HiFi AM sync 8Hz steps 1.6KHz/rev 7KHz filter

- AM Lower sideband sync 8Hz and .8KHz/rev 2.5KHz filter

- AM Upper sideband sync 8Hz and .8KHz/rev 2.5KHz filter

Normal AM uses a 7 kHz filter, and there is also a narrow AM using the 2.5 kHz filter.

Recovered audio is the best I have ever heard on any receiver. I don’t make that claim lightly. It is just so smooth and wonderful to listen to—even using the internal 3” speaker.

Distortion is under 1% in all modes.

The synchronous detectors lock and stay locked. If you tune fast in sync mode, the receiver reverts to regular AM mode at a faster tuning rate and then relocks in sync once tuning is suspended.

In any mode, variable-rate tuning is used. Fast tuning of the main tuning knob will result in a tuning speed of 8x the normal rate in SSB and 6x the normal rate in AM/AM Narrow.

AM sensitivity is 1 µV from 500 kHz to 30 MHz and 0.3 µV if the whip amp is enabled.

SSB sensitivity is better than 0.5 µV from 500 kHz to 30 MHz and under 0.2 µV with the whip amplifier enabled. I have verified these numbers in my lab.

Dynamic range (reciprocal mixing) and 3rd order intermod are also respectable.

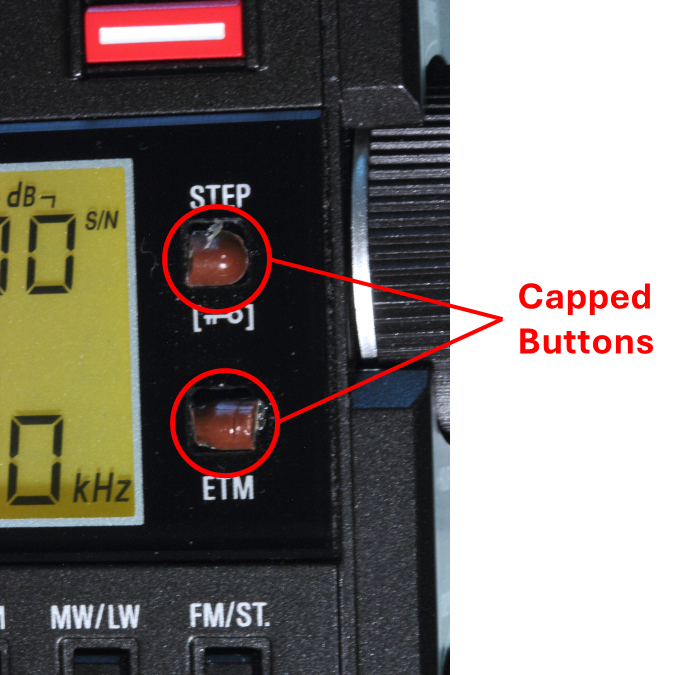

The receiver is simply luxurious to use. I know that is not a technical term, but it describes the receiver very well. The previously described aluminum extruded cabinet can likely be driven over without damage. Encoder tuning combined with the heavy tuning knob is velvet smooth. Black button-head cap screws add to a professional look.

The receiver is simply luxurious to use. I know that is not a technical term, but it describes the receiver very well. The previously described aluminum extruded cabinet can likely be driven over without damage. Encoder tuning combined with the heavy tuning knob is velvet smooth. Black button-head cap screws add to a professional look.

When the 8 batteries are fitted, the receiver weighs in at just over 3 pounds and stays put while tuning or pressing buttons.

Third parties are making the optional keypad, and they may be found on eBay or the Lowe IO group. The same goes for the PL-259-fitted telescoping whip.

Lowe also offered an SP-150 matching speaker and S-meter (audio-derived, I believe) and a very nice preselector (PR-150). Both bring premium prices today.

As the receiver was produced, the LCD did not have backlighting, making it difficult to use, say, bedside at night. As you can see from the first photo, I have backlit mine and those of a number of friends. It is not difficult, but also not for the faint of heart, as it involves delicately removing the silver film on the rear of the LCD display. The Lowe IO group describes a couple of methods for accomplishing backlighting.

There are no surface-mounted parts, and as the main board is uncrowded, repair is easy. There is a long service document that is so in-depth that you could build your own HF-150—assuming you could get the firmware into the microprocessor. I wish other pieces of gear I own were half this detailed.

Jon Thorpe designed one other receiver for Lowe, the HF-250. It is a thing of beauty, also with its 3D black anodized front panel. More filters and features and quite rare today. After designing the HF-250, Jon was hired by AOR, and the well-known AOR7030 was the result.

After Jon left, Lowe did not produce any other receivers I am aware of, but they did privately badge the Palstar R-30 under the Lowe HF-350 model.

I trust the numbers I have provided are reasonably accurate, and if not, Lowe documents will provide better information anyway.

*Note: Users must be very careful not to run the HF-150 from its AC supply while the receiver is fitted with alkaline batteries. The result will be corrosion of the two battery boxes.