Many thanks to SWLing Post contributor, Kostas (SV3ORA), for sharing the following guest post which originally appeared on his radio website:

How to build an automatic rig/antenna switching system

by Kostas (SV3ORA)

When I started collecting vintage rigs, I ended up in a line of rigs on my bench, that were sitting there, disconnected from any mains cables or the antenna. I wanted these rigs to be ready to fire at any time I wanted to, without having to connect/disconnect cables all the time. I also wanted to be able to compare different rigs performances at the flip of a switch, which is the only way this can be done on the HF quick fading conditions. For power cables, the solution was to leave them connected in the mains plugs all the time. My rigs that have an internal PSU, have mechanical switches, so they are isolated from the mains when they are switched off. The rigs that are powered by an external PSU, depend on the external PSU main switch for isolation (in case they haven’t mechanical switches on them), which in my case is mechanical and switches off the mains power, when the PSU is switched off.

However, for the RF cables, this was a different story. Having only one antenna and multiple rigs, means that you have to connect each rig to the antenna every time you want to operate each rig. This is not only boring and time consuming (you have to reach the back of the transceivers to connect/disconnect the connectors), but eventually causes the connectors of the coaxial cable and the rigs to wear out. I decided to make things better and make an RF rig selector for my rigs. This RF rig selector has been described in this link.

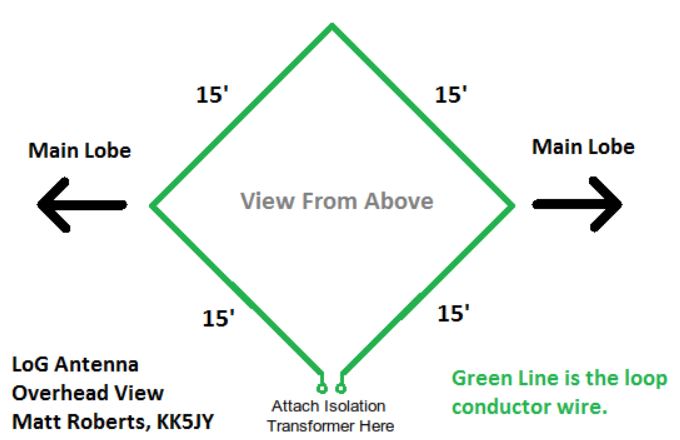

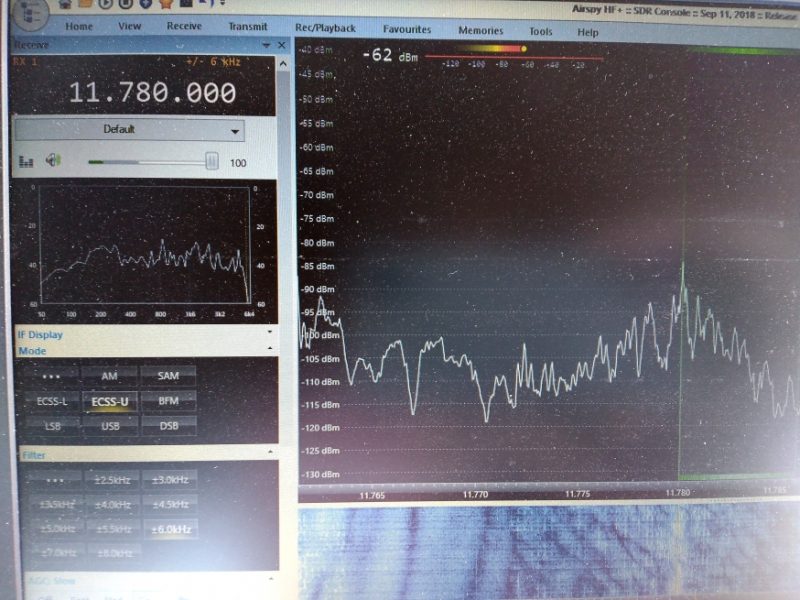

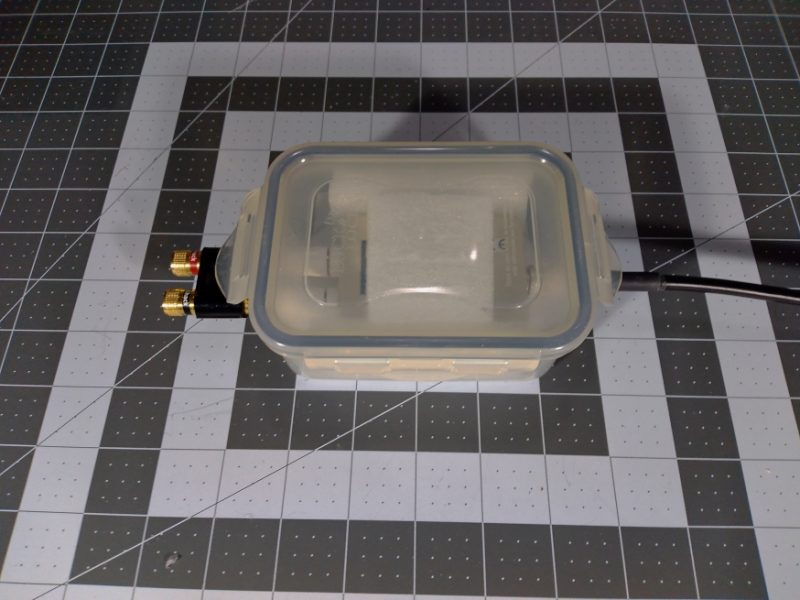

The current antenna I use is fine for transmitting, but in the noisy neighbourhood where I live, it picks up a lot of noise. I have tried many solutions, without significant effect in the noise level. This is why I decided to use a separate antenna for receiving, from that used for transmitting. This antenna will be some kind of loop probably, so as to be immune to noise or insensitive to the direction of the noise. It will be placed in a different location than the transmitting antenna, a location which will be less noisy. Unfortunately, the space I have for the TX antenna lies in a very noisy location in my property. So a separate RX antenna, in another physical location is a must. This means that a separate coaxial for the RX antenna must be used. Thankfully, the RX coaxial can be very small in diameter, passing easily through the sides of the windows, without extra holes.

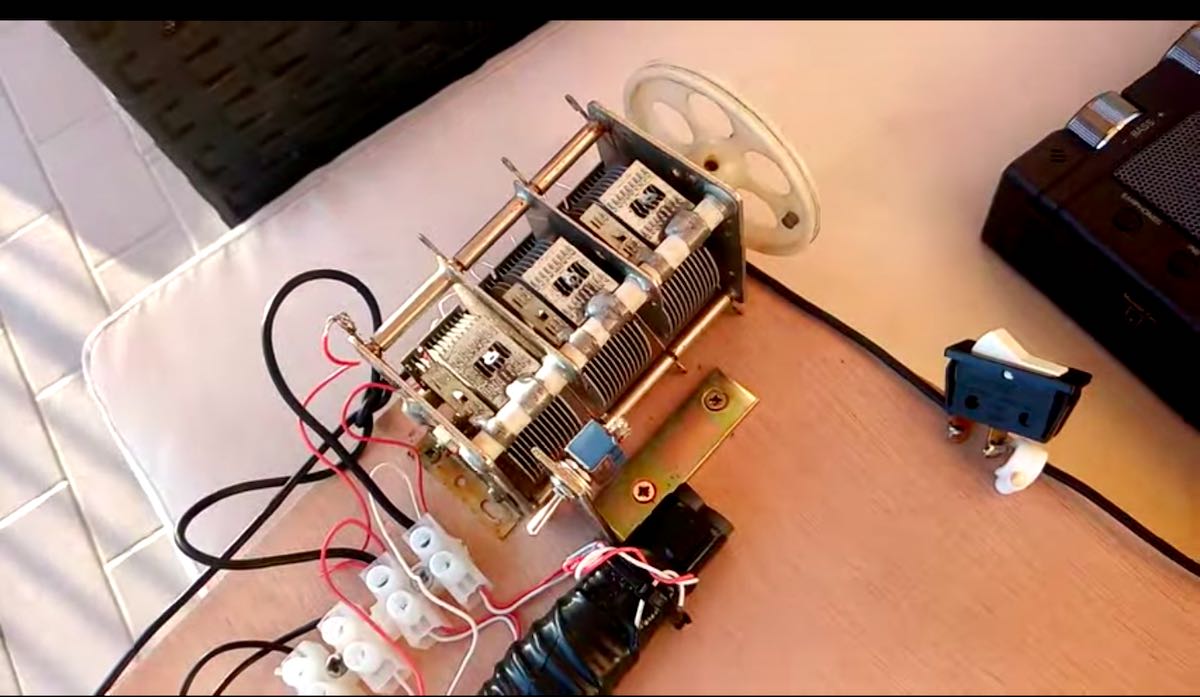

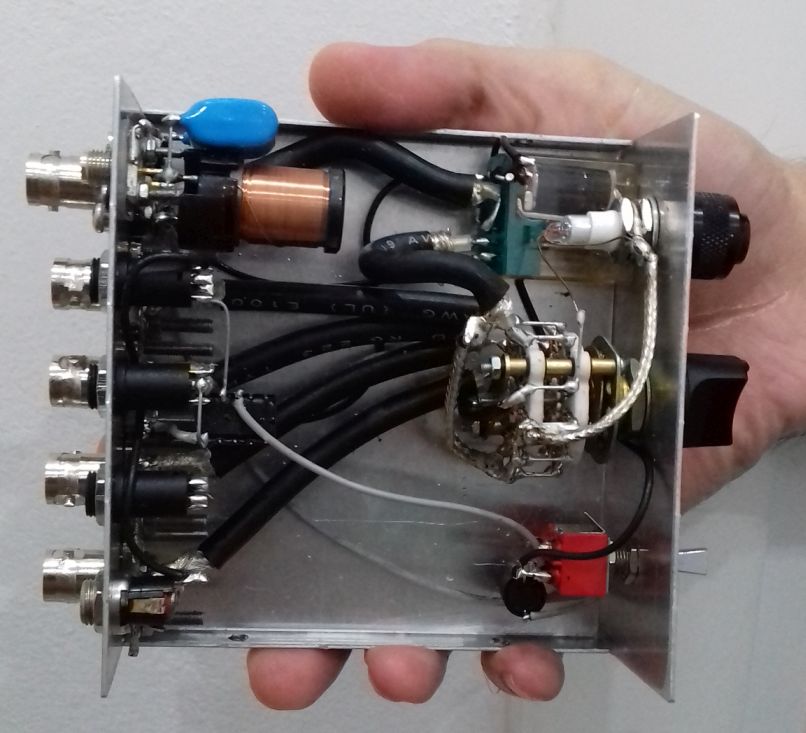

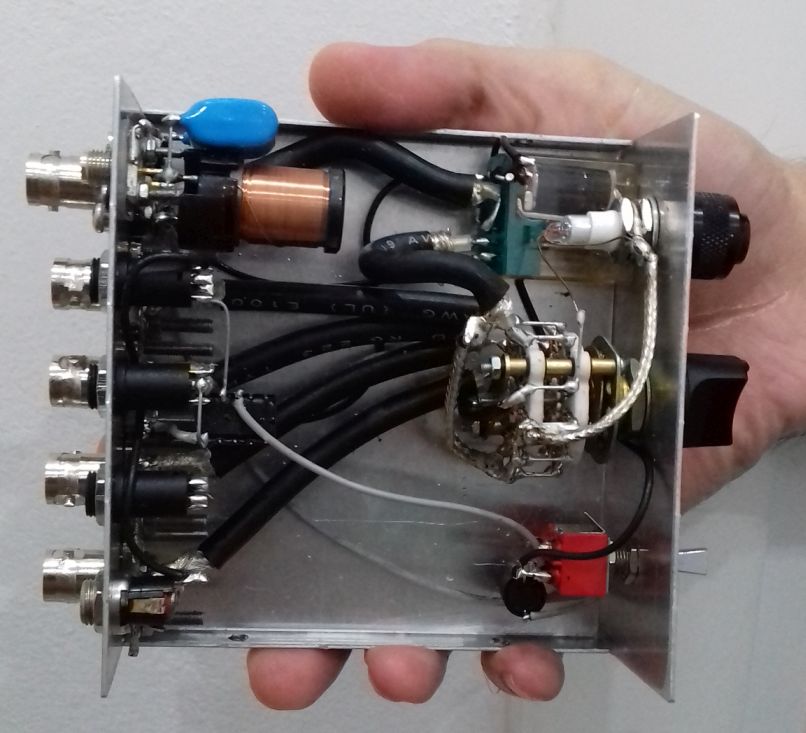

To satisfy all of my requirements, I developed the circuit shown above. The circuit is able to switch a common antenna to four different rigs. Why four? Because this was the capacity of my switch and the number of connectors I had available. If you have a greater capacity switch and more connectors, expand the circuit to your needs.

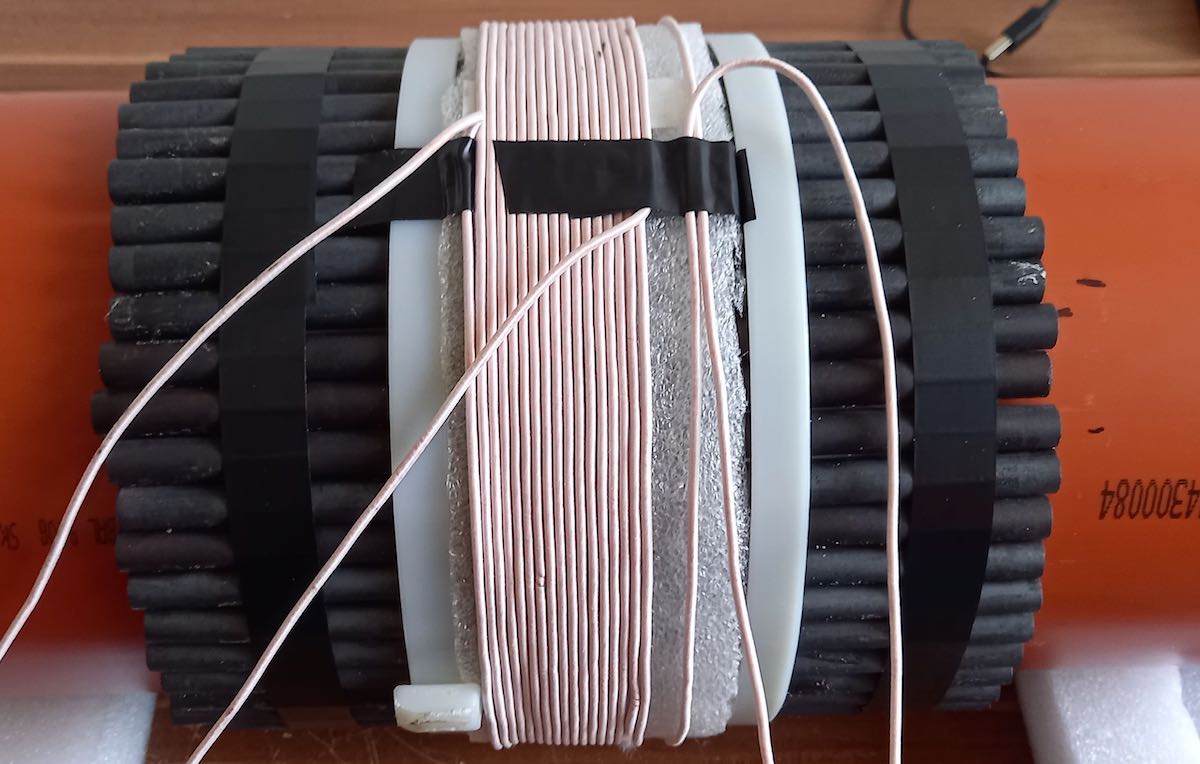

The circuit of the shack switch, allows for 4 separate rigs to be selected, and two antennas, one for RX and one for TX. TX/RX antenna selection is being done automatically (split antenna operation) and controlled by the PTT of any of the rigs connected. This feature can be bypassed by the switch, so that the TX antenna can be used for both RX and TX. The same switch allows also RX operation with passive RX antennas of active ones. When in the active RX antenna position, power is passed to the remote RX preamplifier through the RX coaxial cable, using a bias-T circuit. The values of the bias-T circuit have been chosen very large, so as active RX antennas that operate at LF and lower could still be used. The RF relay defaults in the TX antenna, so that if there is a power failure, or if the circuit is not supplied with power, you can still receive (and transmit) with the TX antenna. The other way around, would be fatal for both the transceiver and the RX antenna (If you transmitted accidentally into it).

The PTT circuits are based on my transceivers. Unfortunately, there is no “standard” for the PTT circuits, each rig has its own way, so the PTT circuits must be thought for each of them. I followed an “inhibit” approach for the PTTs. That is, all the PTT switches are connected in series and DC is passed through them. If any of the rigs transmits, the PTT switch is opened and the circuit switches to the TX antenna. For the rigs that do not have an internal relay but output DC on TX instead, an additional small relay is used (for greater isolation and lossless switching). The only drawback of this “inhibit” topology is that the PTTs of all the rigs must be connected to the circuit simultaneously. If you want to exclude a rig of course, you may short circuit it’s PTT connector in the circuit. The PTT circuits as I said, are non-standard, so you might want to change the circuit to your needs, but anyway you got the idea.

Notice the connections in the circuit. One section of the RF switch (on the left) is used for the positive wire (central conductor of the coaxial) and another for the negative (braid of the coaxial). Why is that? This is because I canted to add a special feature to the switch. That is, the ability to disconnect the antenna from any rig when the rigs are not used. Previously, I used to disconnect the antenna coaxial from the transceiver when I was away, so as to protect the transceiver from antenna static discharges and possibly destroy it’s front end circuits. Now, with a single flip of the switch, I am able to do so. Because I wanted the switch to operate on different types of antennas (balanced or not) I decided to short circuit both poles of the antenna at this position, to equalize their charges.

But equalizing their charges was not enough. I had to find a way to let these charges go to the ground, so that the antenna is discharged. Directly grounding the short circuit, did not seem a good thing to do, because the whole TX wire antenna on the roof would be grounded. Whether this is a good idea to avoid lightings or not, I do not know. So I decided to keep the short circuited antenna floating and instantly discharge it only when adequate static charge is built upon it. For this purpose, I used a neon tube, permanently connected to the switch NC (not-connected) position. When the switch is in the non-connected position, the tube lights up and discharges the antenna (both poles) if an appropriate amount of static charges has been built upon it. When the switch is in any of the selected rigs connections, the tube is disconnected, preventing it from lighting up when you transmit into the antenna. Note that this configuration, requires that the output (antennas) coaxial connectors must be isolated from the metal chassis of the RF switch!

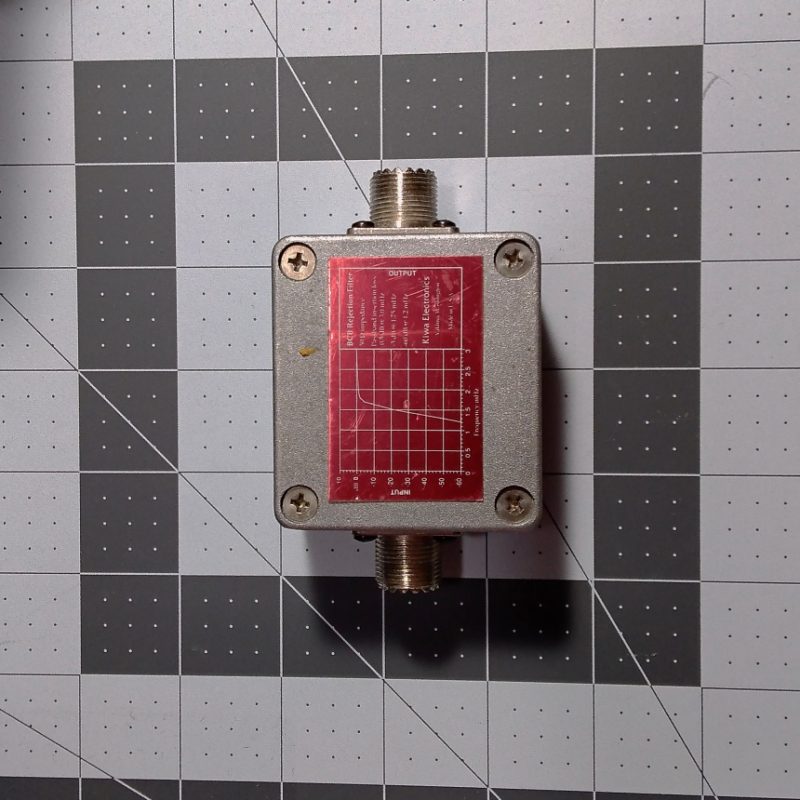

Isolation of the output antenna connectors has been done with a PVC sheet and isolated screw rings. Also note the usage of BNC connectors on TX and SMA on RX. I used BNC connectors for various reasons. They are excellent connectors with quick lock/unlock features. You do not need to screw them (and wear them out) and once fit in place they are not unscrewed. Once fitted in place, they allow for rotating the connection without unscrewing the cable or bending it. They can handle 100W easily. Despite all these features, they are much smaller in size and lighter. Their reduced size fits easily to reduced diameter cables like the RG-58 and similar. In an RF switch where there are lots of cables connected, this does make a difference. They are also very common and very cheap. There are even types that do not require soldering at all to fit a coaxial to them. I use BNC connectors even at my antenna side, as they have been proven to be quite waterproof. The types of BNC connectors I choose are not silver plated. Despite silver plated connectors are better, in the long term they are corroded by humidity and become much worst than the nickel plated connectors. The connectors I used are nickel plated with gold plated central conductors. I have found these types to be much more durable over the years, despite being cheaper. The same goes for the RX SMA connector, but I used an SMA connector there so as to accommodate thinner coaxial cables for RX.

The BNC connectors used, are the square flange types. I used this type of connectors because when they are fitted onto the chassis, they cannot be unscrewed, unlike the single-hole types. For the RX though, I used an SMA connector because it is even smaller and it can accommodate smaller diameter cables. The coaxial cable used for the internal switch connections on TX, is the RG-223. This cable is silver-plated (both the central conductor and the braid), it has double braid for increased shielding, it is of the same diameter as the RG-58 and it has a bit lower loss. The cable loss is negligible though for such small pieces of cable. The same type of cable has been used for the internal switch-relay connections as well as for the connections of the selector to the rigs. Appropriate lengths of RG-223 cables were cut and fitted with BNC connectors at one side and the appropriate rig connectors at their other side. For the RX antenna, you may use the thinner diameter cable you can find. I used a small piece of very thin coaxial (taken out of the WiFi card of an old laptop) and passed this piece through the side of the windows of the shack and through the mosquito net of the windows. No extra holes are required that way! For the rest of the RX cable, you can use whatever cable diameter you want, but I tried to use the smallest diameter I could find, so that the cable is as much phantom as possible.

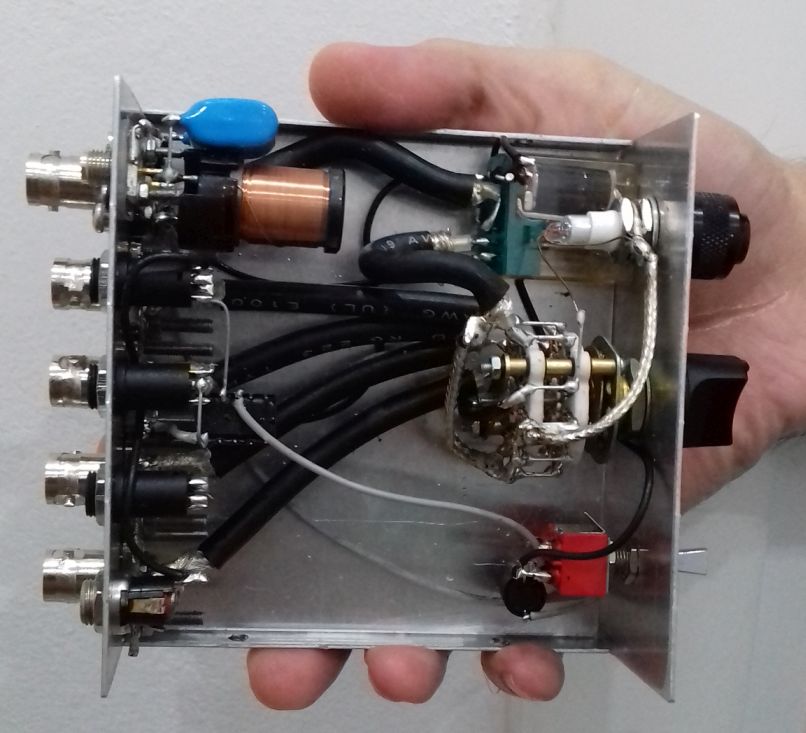

All the coaxial rig cables are grounded at the connectors side. I used a piece of coaxial braid and fitted it to the connectors screws. Then I soldered the braids of the coaxial cables onto this piece. Notice the black ring screw isolators at the antenna connector, to isolate it from the chassis. Speaking about the chassis, do not use a plastic chassis for the RF switch, use only a metal one! The picture below, as well as all the next pictures, show the RF cables arrangement, but note that the circuit in these pictures is not complete yet.

The coaxial cables are soldered onto the switch contacts. Where a ground connection is required, a piece of braid accomplishes this. Do not use thin wires, the device has to allow for at least 100W of HF RF power to pass through it. I have tested the switch with 200W of power and there were no problems at all. The neon tube directly connects to the appropriate switch contact and to the chassis.

The most important part of an RF switch is of course the switch itself. For 100W of HF RF power, I would suggest you to use a porcelain switch. I had a 5-positions 4-sections small porcelain switch, which I used. I connected two sections at each side in parallel (adjacent pins connected together). That is, two sections in parallel for the positive wire and two sections in parallel for the braid. I did that for various reasons. First, by using two contacts for each connection instead of one, you increase the power handling capability of the switch. Then, you ensure a sure-contact throughout the years. Any corrosion or wearing on the switch contacts would cause contact problems eventually. By using two contacts for each connection instead of one, you double the probability for a good contact. After all, I had a switch with more sections, so why not make a good use of them?

The completed selector is shown above. The relay was been taken out of an old CB radio. Use the best quality relay you can afford, as this will be switched quite often and it must handle at least 100W of RF power.

The results from the RF switch operation are quite satisfying. The overall construction is kept small and low profile. The switch makes a good contact despite being small. The automatic discharger seems to work well. On receive, there is some RF leakage, as I expected, in the near by cables, which is noticed in the higher HF bands or in very strong signals. The very sensitive receivers we use, are able to detect that. This RF leakage occurs even when the switch is in the NC position, where the antenna is disconnected and floating. So, to be honest I have not figured out if the leakage is from the switch or from the external cables in the shack. On TX, there is of course severe leakage from the transmitting coaxial to the rest of the ports. This IS expected. There is leakage even without using any selector at all, in the nearby receivers, when a transmitter operates at such high powers. There is nothing you can do about it really, unless your receiver has a mute capability, which I did not bother to take care of.

The TX/RX switching is taken care automatically and this is very useful and relaxing for the operator as he does not have to worry about anything. The active or passive RX antenna selector and the feature to disable the auxiliary RX antenna are really useful and you can do many antenna and rigs comparisons on-the-fly with it, by the flip of a switch. Depended on the noise level and the sensitivity you want to achieve, the switch will provide you the most optimal RX conditions instantly!

The most important thing though, is that the goal of this project was achieved. I am able to switch the antenna to whatever rig I want at the flip of a switch. And before I go away, at the flip of a switch I can isolate and automatically discharge the antenna when needed. This is so much more convenient than having to connect and disconnect cables all the time. I can also now use a separate antenna for RX, which greatly improves reception in my case. This antenna is automatically switched by any rig I have and I do not have to worry about anything. I can also do comparisons between different antennas on RX, which is crucial in deciding which antenna is better for receiving. All these features make this little simple to build circuit, so useful and an integral part of the shack.

Thank you for sharing this practical and affordable project with us, Kostas!

Post Readers: Check out this project and numerous others on Kostas’ excellent website.