SWLing Post contributor, Gary DeBock, is an acclaimed innovator in the realm of Ultralight DXing–he’s well-known for constantly pushing the envelop on these inexpensive DX receivers.

SWLing Post contributor, Gary DeBock, is an acclaimed innovator in the realm of Ultralight DXing–he’s well-known for constantly pushing the envelop on these inexpensive DX receivers.

Gary has published yet another detailed home-brew project that can turn your stock Tecsun PL-380 into a Mediumwave DX Fiend!

Many thanks to Gary for the following guest post:

“Pest Control” 4.25” FSL Tecsun PL-380

Put Your Local Noisemakers Down for the Count with this Breakthrough Model

By Gary DeBock, Puyallup, WA, USA

February 2016

Introduction

The first portable radio with a transplanted FSL antenna was introduced last month (click here to read), providing breakthrough MW-DXing performance in the pocket radio class. Although this 3” Bar FSL Tecsun PL-380 exceeded expectations in every way, its 100mm ferrite bars were in very short supply.

By coincidence the final eBay seller of these 100mm x 20mm x 3mm Russian surplus bars (in Romania) stopped selling them on the day that the first model was finished, creating an instant rush in demand. After providing twelve sets (of 8 bars each) to various DXers my own stock of these bars was rapidly dwindling, and it became an urgent matter to design a similar model using the plentiful 62mm x 12mm x 4mm ferrite bars. Sensitivity of the new FSL antenna would need to be fully competitive with the original model, and I was hopeful of a design that would offer at least one new DXing advantage.

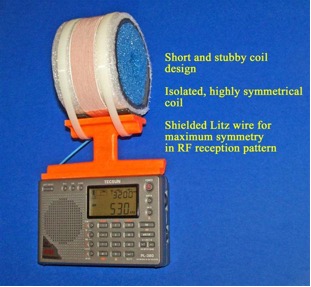

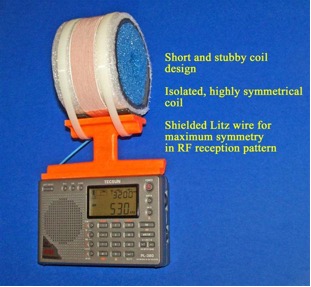

With the shorter (62mm bars) it would require a larger diameter FSL antenna to come close to the original model in sensitivity, so by necessity this alternative model would need to have a “short and stubby” FSL coil design. After considering this I recalled that most of the antennas with a reputation for exceptional nulling performance (and direction finding) seemed to have such a “short and stubby” coil design—so why not take this opportunity to design and create a portable radio with breakthrough nulling performance, in addition to its superior sensitivity? Such a combination would hopefully make the new model an innovative performer in urban areas—a portable radio that could not only silence multiple MW “pest” stations, but also provide unusual sensitivity to receive competing stations right on the same frequencies. As the model was developed several technical discoveries were made to improve nulling performance, such as the use of grounded shield foil for the Litz wires, and an ultra-symmetrical FSL coil. But even if you live in a rural area far from any MW stations, you will find that this modified radio has a great deal of performance to offer— a combination of sensitivity, selectivity and nulling ability that has never existed in portable form.

Project Overview

This modification procedure will convert the Tecsun PL-380 AM-LW-FM-SW portable from a modest-performing Medium Wave receiver into an exceptional one, with a significant enhancement of Longwave performance as well. The process involves some close-order soldering on a crowded PL-380 circuit board, and should only be attempted by those will good close-up eyesight, steady hand coordination and some soldering experience. The process also involves the winding of a highly symmetrical antenna coil, which is essential for optimal nulling performance. Because of this, careful attention to the instructions and the use of the recommended ferrite bars and Litz wire is important for the best performance. Certain component parts may be in short supply depending upon current demand, and it is recommended that all these be collected prior to starting the modification procedure.

Since major portions of this project involve duplication of procedures contained in the PL-380 7.5” Loopstick Transplant article, reference is made to various steps and instructions in that article (posted here). As such, hobbyists who have successfully completed the 7.5” loopstick transplant project on a PL-380 will find this procedure relatively simple, with only the 4.25” Bar FSL construction as a new challenge. The resulting FSL-enhanced PL-380 truly provides a quantum leap in MW-DXing performance over the stock model, but reasonable care is necessary to protect the modified portable from sudden drops or mechanical shocks. Completion of the finished radio should provide a great level of satisfaction and hobby enjoyment, especially during travel opportunities where external antennas are impractical or forbidden.

Construction Parts Required

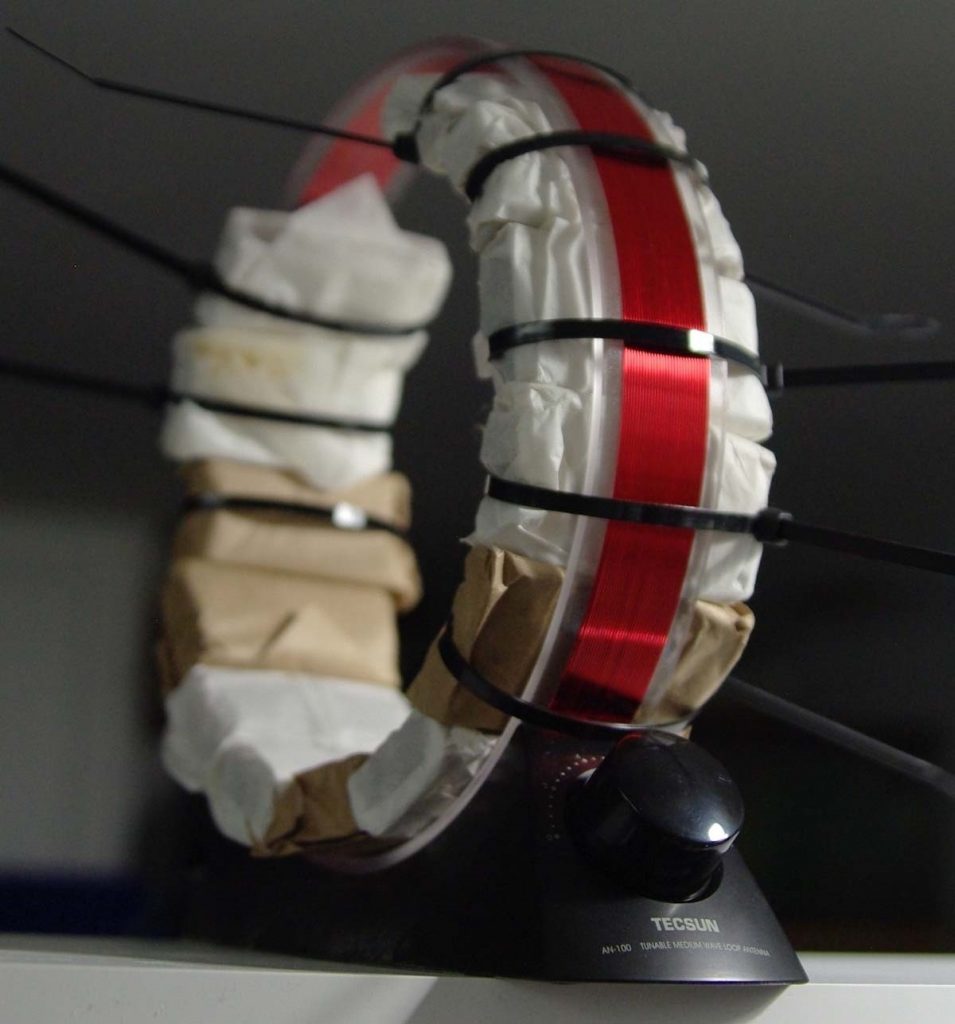

A.) Tecsun PL-380 AM-LW-FM-SW Receiver (available from multiple sources on eBay)

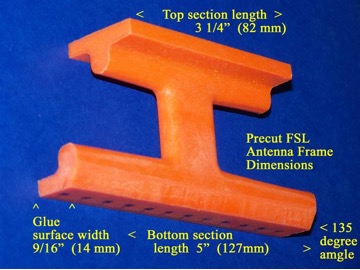

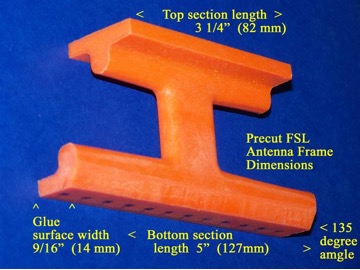

B.) Precut section of Ace Hardware 48″ orange plastic carpenter’s level (dimensions to follow)

C.) 2.6″ long section of the 3.5″ diameter “Big Boss Noodle“

D.) 22 Russian surplus 62mm x 12mm x 4mm ferrite bars

E.) Tube of Duro Super Glue, .07 ounce (or equivalent)

F.) Two 1″ x 1/2″ strips of 1″ I.D. rubber heater hose

G.) 7 1/2″ of 1/8″ diameter shrink tubing

H.) Two 18″ long plastic tie wraps, 125 lb. test

I.) Oatey 4″ x 4″ foam closet spacer pack

J.) Roll of Rite Aid 1″ wide waterproof tape

K.) 40 feet of 250/46 Litz wire

L.) Roll of Scotch “Extreme” shipping tape (any size)

Miscellanious:

- 8 1/2” x ¾” strip of heavy duty aluminum foil (Reynolds or equivalent)

- 3” long #18 hookup wire

- 25w pencil-type soldering iron

- solder

- hacksaw (or power miter saw)

- hand tools

PL-380 Preparation

Before voiding the warranty on your new PL-380, it’s a good idea to ensure that it has no existing problems which might require warranty service J Install batteries in the radio and give it a test run on all four bands, checking the tuning encoder, clock, volume control, speaker, headphone jack, display functions and digital searching modes. Make sure that the radio is working properly in all functions before starting the modification procedure, since the eBay sellers are unlikely to show you any sympathy after you tear out the stock loopstick. It’s also a good idea to check out the Medium Wave weak signal reception with the PL-380 stock loopstick before starting the modification, to establish a benchmark of performance against which the new 4.25” FSL’s DXing performance will be compared.

Step-By-Step Construction

1) Follow the detailed cutting procedures in steps 1-9 of the loopstick transplant article (using either a power miter saw or hacksaw) to prepare the FSL antenna mounting frame, HOWEVER please note that the top section length for this project is 3 1/4” (82 mm), NOT 8” as in the loopstick transplant project. The finished precut frame should resemble the picture to the left, with the top section flat, and the bottom section back edge trimmed to allow full use of the radio’s whip antenna. The frame’s entire bottom section (including the glue surface) is identical in both the loopstick and FSL transplant projects.

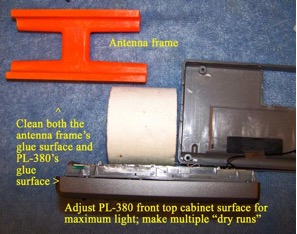

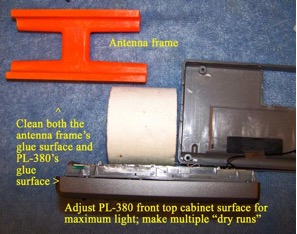

2) Follow the detailed procedures in steps 17-22 of the loopstick transplant article to prepare the PL-380 cabinet for the FSL transplant procedure.

3) Refer to the photo above (NOTE: These photos show the original FSL frame cut for the longer 100mm bars, which has a longer top section length than the 3 1/4” on this project’s FSL frame. Ignore this aspect). Place the prepared PL-380 cabinet in the vertical position as shown, with a paper roll (or other item) to keep the cabinet in the vertical position. If necessary sand the edges (only) of the antenna frame’s glue surface to ensure that no cutting debris or rough edges will cause an uneven gluing surface. Use a clean, damp cloth or paper towel to remove all dust and debris from both the antenna frame and PL-380 glue surfaces, then wipe them thoroughly dry. Ensure that maximum light shines on the PL-380’s top glue surface (as shown in the photo below), then practice making multiple “dry runs” of placing the antenna frame directly centered on the PL-380’s front top cabinet surface, with its front edge lined up with the PL-380’s beveled front edge. You will only get one chance to place the frame accurately when the super glue is on the PL-380 surface, so make sure that you know exactly what to do! The antenna frame should sit completely flat against the PL-380 cabinet, and slide across it smoothly if such a test is made. If not, sand any rough edges on the antenna frame’s glue surface and repeat the cleaning procedure.

4) Refer to the photo above. After ensuring that you are fully prepared for accurate placement of the antenna frame on the PL-380 cabinet, place a 4 1/2” x 3/16” bead of super glue (114 mm x 5 mm) on the PL-380’s front top cabinet surface, as shown in the photo. Refer to the photo on the top of the next page. Ensure that the front side of the antenna frame (as shown) is facing you, then place the antenna frame in a centered position flat against the PL-380 cabinet, with its front edge lining up with the front beveled edge of the cabinet, as shown in the photo. Press the antenna frame down firmly against the cabinet for about one minute, scraping away any excess glue from the front and back edges with a small, flat jeweler’s screwdriver. It is especially important to remove any excess glue from the back edge of the antenna frame in order to allow the PL-380’s back cabinet to close normally. After completion of this step place the PL-380 (with the attached antenna frame) in a secure area until the FSL antenna is constructed.

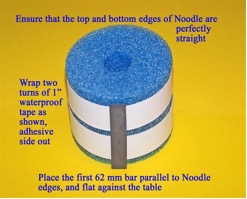

Construction of FSL Antenna

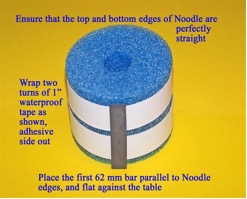

5) Refer to the photo at right. Take the precut section of “Big Boss Noodle,” and ensure that the top and bottom cut faces are perfectly straight. Place the section flat on the table as shown, and carefully wrap two lengths of the 1” waterproof tape tightly around the noodle’s circumference, adhesive side out (as shown). Ensure that these tape strips are parallel, and tight enough not to slide up or down. Take a perfectly straight 62 mm bar and press it tightly up against the tape as shown, with its lower edge flat on the table and its longer edges parallel to the noodle’s edges.

6) Refer to the photo at right. Carefully press the remaining 21 bars against the waterproof tape, ensuring that their lower edges are flat against the table, and that there are no major gaps in between any bars. (NOTE: These bars occasionally have slightly curved edges, and it may be necessary to turn them upside down or backwards in order for them to fit in well with the adjacent bars. When all of the bars are carefully placed, 22 of them will fit exactly on the noodle’s circumference. If necessary, pull certain bars off of the tape and reposition them for a better fit).

6) Refer to the photo at right. Carefully press the remaining 21 bars against the waterproof tape, ensuring that their lower edges are flat against the table, and that there are no major gaps in between any bars. (NOTE: These bars occasionally have slightly curved edges, and it may be necessary to turn them upside down or backwards in order for them to fit in well with the adjacent bars. When all of the bars are carefully placed, 22 of them will fit exactly on the noodle’s circumference. If necessary, pull certain bars off of the tape and reposition them for a better fit).

When all 22 bars are positioned in a tidy pattern, wrap two strips of the waterproof tape tightly around them as shown, with the adhesive side out. It is OK if the two tape strips slightly overlap (as shown in the photo), but the two strips should be tight enough so that they don’t slide up or down, and also tight enough to secure the ferrite bar assembly in a circular pattern.

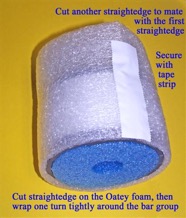

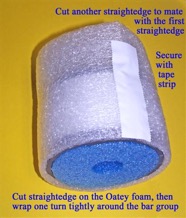

7) Refer to the photo at right. Remove the inner staple from the Oatey foam, and locate a 14” (35 cm) length of the foam which is free of holes or imperfections. Cut a straightedge at the beginning of this 14” (35 cm) length of foam, and press this foam edge down on the tape at the position shown in the photo at right, perpendicular to the side of the bar assembly and with one edge of the foam length lined up with one edge of the bar assembly. Wrap the foam length tightly around the circumference of the bar assembly, stretching it slightly to keep it completely flat and lined up with the bar assembly edge. After the foam strip is tightly and completely wrapped around the bar assembly cut another straightedge to mate evenly with the first straightedge, ensuring that there are no gaps or overlaps along the two edges. If necessary, re-stretch and trim the foam strip to mate evenly with the first edge. After once again ensuring a tight wrap of the Oatey foam, secure the two edges with a 3” (76 mm) strip of waterproof tape, as shown in the photo on the previous page.

7) Refer to the photo at right. Remove the inner staple from the Oatey foam, and locate a 14” (35 cm) length of the foam which is free of holes or imperfections. Cut a straightedge at the beginning of this 14” (35 cm) length of foam, and press this foam edge down on the tape at the position shown in the photo at right, perpendicular to the side of the bar assembly and with one edge of the foam length lined up with one edge of the bar assembly. Wrap the foam length tightly around the circumference of the bar assembly, stretching it slightly to keep it completely flat and lined up with the bar assembly edge. After the foam strip is tightly and completely wrapped around the bar assembly cut another straightedge to mate evenly with the first straightedge, ensuring that there are no gaps or overlaps along the two edges. If necessary, re-stretch and trim the foam strip to mate evenly with the first edge. After once again ensuring a tight wrap of the Oatey foam, secure the two edges with a 3” (76 mm) strip of waterproof tape, as shown in the photo on the previous page.

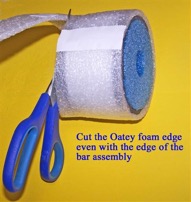

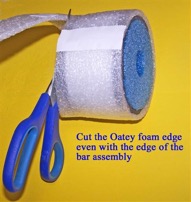

8) Place the assembly in the position shown in the photo at right. Take scissors and trim the loose edge of the Oatey foam so that it is even with the other edge of the bar assembly, as shown in the photo at left. After this trimming both edges of the assembly should be flat, with the assembly forming a perfect cylindrical shape (as shown).

8) Place the assembly in the position shown in the photo at right. Take scissors and trim the loose edge of the Oatey foam so that it is even with the other edge of the bar assembly, as shown in the photo at left. After this trimming both edges of the assembly should be flat, with the assembly forming a perfect cylindrical shape (as shown).

9) Refer to the photo below:

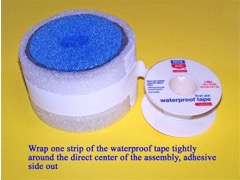

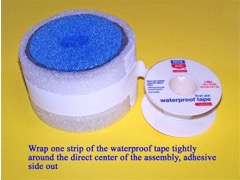

Place the assembly on one of its edges, as shown. Take the waterproof tape and tightly wrap one strip along the direct center of the assembly as shown, with the adhesive side out. Ensure that this strip of tape is tight enough so that it will not slide up or down by itself, and then cut the tape with a 2” (51 mm) overlap. If necessary (after wrapping this tape), shift the position of the tape slightly to ensure that it is running along the direct center of the assembly before proceeding with the next step.

Place the assembly on one of its edges, as shown. Take the waterproof tape and tightly wrap one strip along the direct center of the assembly as shown, with the adhesive side out. Ensure that this strip of tape is tight enough so that it will not slide up or down by itself, and then cut the tape with a 2” (51 mm) overlap. If necessary (after wrapping this tape), shift the position of the tape slightly to ensure that it is running along the direct center of the assembly before proceeding with the next step.

10) NOTE: The symmetry of your Litz wire coil will be a major factor in determining the nulling capability of your modified PL-380. When winding the coil keep the Litz wire turns as tight and straight as possible, with no gaps or overlaps.

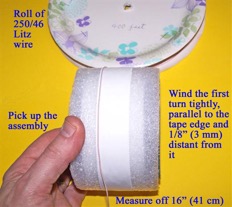

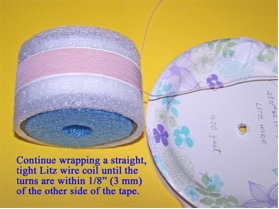

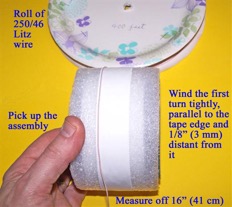

Refer to the photo on the right. Take the roll of 250/46 Litz wire and measure off 16” (41 cm) from the end. While holding this Litz wire point with one hand pick up the bar assembly with the other hand, and press down the (16”) Litz wire point with the wire parallel to the edge of the tape and 1/8” (3 mm) distant from it, as shown in the photo at left. Keep thumb pressure on this (16”) point while carefully winding a tight first turn of Litz wire around the circumference of the bar assembly, accurately maintaining the 1/8” (3 mm) distance from its edge. After this first Litz wire turn is wound tightly and accurately around the bar assembly it will set the pattern for the remaining turns, which only need to be tightly wound adjacent to the preceding turn.

Refer to the photo on the right. Take the roll of 250/46 Litz wire and measure off 16” (41 cm) from the end. While holding this Litz wire point with one hand pick up the bar assembly with the other hand, and press down the (16”) Litz wire point with the wire parallel to the edge of the tape and 1/8” (3 mm) distant from it, as shown in the photo at left. Keep thumb pressure on this (16”) point while carefully winding a tight first turn of Litz wire around the circumference of the bar assembly, accurately maintaining the 1/8” (3 mm) distance from its edge. After this first Litz wire turn is wound tightly and accurately around the bar assembly it will set the pattern for the remaining turns, which only need to be tightly wound adjacent to the preceding turn.

Since the waterproof tape is wound with the adhesive side out on the assembly, if you need to take a break while winding the Litz wire coil place the assembly down on its edge, not on the adhesive side of the tape. Wrap the second turn tightly adjacent to the first turn, checking around the circumference of the assembly to ensure that there are no gaps or overlaps in the Litz wire turns. Continue this careful process until the entire coil has been wound, as described in the next step.

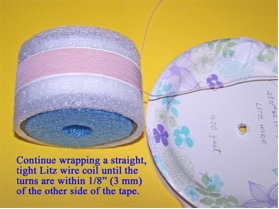

11) Refer to the photo at right. Continue winding tight, straight turns of Litz wire (with no gaps or overlaps) until the turns are within 1/8” (3 mm) of the other side of the tape. At this point you should have around 21 turns in your Litz wire coil, although the number of turns is not nearly as important as the symmetry of your coil. It should appear completely straight down the center of the assembly, as in the photo at right.

11) Refer to the photo at right. Continue winding tight, straight turns of Litz wire (with no gaps or overlaps) until the turns are within 1/8” (3 mm) of the other side of the tape. At this point you should have around 21 turns in your Litz wire coil, although the number of turns is not nearly as important as the symmetry of your coil. It should appear completely straight down the center of the assembly, as in the photo at right.

12) Refer to the photo below.

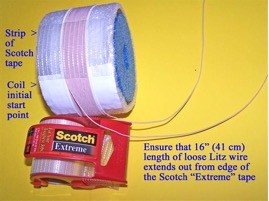

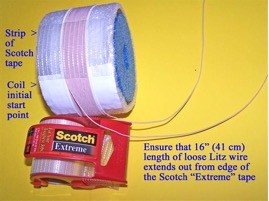

Take the Scotch “Extreme” tape and place a strip across the Litz wire coil at the exact start point (where the 16” point was first pressed down on the tape), ensuring that 16” of loose Litz wire still extends beyond this point for hookup purposes. Ensure that the “Extreme” tape strip is perfectly perpendicular to the Litz wire coil, and that there are no “bubbles” or major wrinkles along its length. Press this tape strip firmly down over the Litz wire coil to secure the coil in a symmetrical position, then trim the ends of the tape even with the edges of the bar assembly.

Take the Scotch “Extreme” tape and place a strip across the Litz wire coil at the exact start point (where the 16” point was first pressed down on the tape), ensuring that 16” of loose Litz wire still extends beyond this point for hookup purposes. Ensure that the “Extreme” tape strip is perfectly perpendicular to the Litz wire coil, and that there are no “bubbles” or major wrinkles along its length. Press this tape strip firmly down over the Litz wire coil to secure the coil in a symmetrical position, then trim the ends of the tape even with the edges of the bar assembly.

13) NOTE: To the maximum extent the two ends of the Litz wire coil should be secured by the Scotch “Extreme” tape so that they leave the coil as close together as possible, with no loose runs of single Litz wire along the coil. This factor (along with the use of a grounded shield around the lead-in Litz wires) has proven to have a major effect on the nulling capability of the FSL coil.

Refer to the photo at right. Place a second strip of Scotch “Extreme” tape across the Litz wire coil directly below and within 1/8” (3 mm) of the first strip, securing the other end of the coil where the Litz wire leaves the assembly. Once again ensure that 16” (41 cm) of loose Litz wire extends from the coil, then cut the Litz wire at that 16” (41 cm) point. Ensure that both Litz wires leave the coil freely without binding or kinks, and that the second strip of “Extreme” tape also has no “bubbles” or major wrinkles along its length. Press this second strip of “Extreme” tape firmly down over the coil to finally secure the coil in a symmetrical position, then once again trim the ends of the tape even with the edges of the bar assembly.

Refer to the photo at right. Place a second strip of Scotch “Extreme” tape across the Litz wire coil directly below and within 1/8” (3 mm) of the first strip, securing the other end of the coil where the Litz wire leaves the assembly. Once again ensure that 16” (41 cm) of loose Litz wire extends from the coil, then cut the Litz wire at that 16” (41 cm) point. Ensure that both Litz wires leave the coil freely without binding or kinks, and that the second strip of “Extreme” tape also has no “bubbles” or major wrinkles along its length. Press this second strip of “Extreme” tape firmly down over the coil to finally secure the coil in a symmetrical position, then once again trim the ends of the tape even with the edges of the bar assembly.

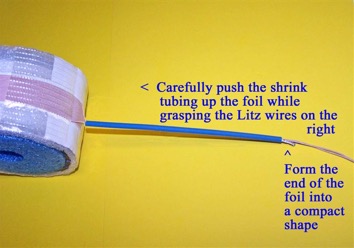

14) Refer to the photo above. Take the FSL assembly, 8 1/2” x 3/4” strip of aluminum foil and the 7 1/2” length of 1/8” shrink tubing and place them in the positions shown. Place the strip of aluminum foil under the Litz wires, with the Litz wires running about 1/4” from the right edge of the strip of aluminum foil. Starting as close as possible to the FSL coil (where the Litz wires leave the coil), make a lengthwise fold in the aluminum foil from right to left, covering over the Litz wires for the first 7 1/2” of the aluminum foil (leave 1” at the end of the foil, which will not be folded).. Ensure that the Litz wires are within this initial fold for the 7 1/2” length, then make a second lengthwise fold in the aluminum foil from left to right to securely wrap the Litz wires inside the foil for this first 7 1/2” length. Finally form the aluminum foil into a tight circle as shown, ensuring that neither of the Litz wires is exposed throughout this 7 1/2” length of the foil, and that they are both tightly wrapped in the foil. Also ensure that this entire length of the foil-wrapped Litz wires is of a small enough diameter to easily pass through the 1/8” shrink tubing.

14) Refer to the photo above. Take the FSL assembly, 8 1/2” x 3/4” strip of aluminum foil and the 7 1/2” length of 1/8” shrink tubing and place them in the positions shown. Place the strip of aluminum foil under the Litz wires, with the Litz wires running about 1/4” from the right edge of the strip of aluminum foil. Starting as close as possible to the FSL coil (where the Litz wires leave the coil), make a lengthwise fold in the aluminum foil from right to left, covering over the Litz wires for the first 7 1/2” of the aluminum foil (leave 1” at the end of the foil, which will not be folded).. Ensure that the Litz wires are within this initial fold for the 7 1/2” length, then make a second lengthwise fold in the aluminum foil from left to right to securely wrap the Litz wires inside the foil for this first 7 1/2” length. Finally form the aluminum foil into a tight circle as shown, ensuring that neither of the Litz wires is exposed throughout this 7 1/2” length of the foil, and that they are both tightly wrapped in the foil. Also ensure that this entire length of the foil-wrapped Litz wires is of a small enough diameter to easily pass through the 1/8” shrink tubing.

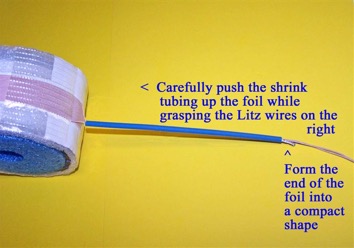

15) Refer to the photo at right. Form the 1” end of the aluminum foil (which does not wrap around the Litz wires) into a compact cylindrical shape, as shown (NOTE: the foil is relatively fragile, and should be handled carefully). Take the loose ends of the Litz wires and pass them through the 1/8” shrink tubing, including the prepared end of the aluminum foil as it approaches that point. While grasping the Litz wires on the right side (as shown) carefully slide the shrink tubing toward the FSL coil, ensuring that it smoothly covers over the foil-wrapped Litz wires (if not, continue forming the aluminum foil into a smaller diameter so that the shrink tubing will easily cover over it. This process should go smoothly with proper preparation). When the shrink tubing is completely covering up the foil-wrapped Litz wires the last 1” section of the aluminum foil should be extending out of the right side of the shrink tubing, as shown in the photo. Handle this aluminum foil section with care in the remaining steps—it is relatively fragile, and should never be pulled for any reason.

15) Refer to the photo at right. Form the 1” end of the aluminum foil (which does not wrap around the Litz wires) into a compact cylindrical shape, as shown (NOTE: the foil is relatively fragile, and should be handled carefully). Take the loose ends of the Litz wires and pass them through the 1/8” shrink tubing, including the prepared end of the aluminum foil as it approaches that point. While grasping the Litz wires on the right side (as shown) carefully slide the shrink tubing toward the FSL coil, ensuring that it smoothly covers over the foil-wrapped Litz wires (if not, continue forming the aluminum foil into a smaller diameter so that the shrink tubing will easily cover over it. This process should go smoothly with proper preparation). When the shrink tubing is completely covering up the foil-wrapped Litz wires the last 1” section of the aluminum foil should be extending out of the right side of the shrink tubing, as shown in the photo. Handle this aluminum foil section with care in the remaining steps—it is relatively fragile, and should never be pulled for any reason.

16) Refer to the photo at right. Place the viously prepared PL-380 and antenna frame assembly flat on the table, with a protective cloth to keep the front panel display from damage. Take the prepared FSL antenna assembly and place it in the position shown, with the shielded Litz wire shrink tubing running along the back side of the antenna frame, and with the lower edge of the FSL assembly next to the top of the antenna frame. Place the two 1” x 1/2” strips of rubber heater hose in the two positions shown, in between the antenna frame and the FSL antenna and also in between the coil and the FSL edges, with the longer rubber strip dimensions parallel to the FSL edges. Start the two 175 lb. test plastic tie wraps in the positions shown (down the center of the rubber spacer strips), ensuring that the rubber spacer strips remain between the FSL assembly and the antenna frame, and that the spacer strips are centered at the very bottom of the FSL assembly. Also ensure that the Litz wires are in the position shown, with no pinching or binding between the FSL assembly and antenna frame. Slowly and carefully tighten the first plastic tie wrap while ensuring that the rubber spacer strip remains in the proper position. Tighten this plastic tie wrap only enough to securely hold the FSL assembly, and do not tighten it to the point where the ferrite bars’ circular pattern becomes distorted. In a similar manner, carefully tighten the other plastic tie wrap while ensuring that the rubber spacer strip remains in the centered position, in between the antenna frame and FSL assembly. Once again, tighten this tie wrap only enough to securely hold the FSL assembly, and not to the point where the ferrite bars’ circular pattern becomes distorted. When this process is complete the large plastic tie wraps’ clamps should be in the position shown, lined up with each other and in a position to support the radio/FSL combination when the model is laying down flat, on a table. Cut off the excess tie wrap lengths.

16) Refer to the photo at right. Place the viously prepared PL-380 and antenna frame assembly flat on the table, with a protective cloth to keep the front panel display from damage. Take the prepared FSL antenna assembly and place it in the position shown, with the shielded Litz wire shrink tubing running along the back side of the antenna frame, and with the lower edge of the FSL assembly next to the top of the antenna frame. Place the two 1” x 1/2” strips of rubber heater hose in the two positions shown, in between the antenna frame and the FSL antenna and also in between the coil and the FSL edges, with the longer rubber strip dimensions parallel to the FSL edges. Start the two 175 lb. test plastic tie wraps in the positions shown (down the center of the rubber spacer strips), ensuring that the rubber spacer strips remain between the FSL assembly and the antenna frame, and that the spacer strips are centered at the very bottom of the FSL assembly. Also ensure that the Litz wires are in the position shown, with no pinching or binding between the FSL assembly and antenna frame. Slowly and carefully tighten the first plastic tie wrap while ensuring that the rubber spacer strip remains in the proper position. Tighten this plastic tie wrap only enough to securely hold the FSL assembly, and do not tighten it to the point where the ferrite bars’ circular pattern becomes distorted. In a similar manner, carefully tighten the other plastic tie wrap while ensuring that the rubber spacer strip remains in the centered position, in between the antenna frame and FSL assembly. Once again, tighten this tie wrap only enough to securely hold the FSL assembly, and not to the point where the ferrite bars’ circular pattern becomes distorted. When this process is complete the large plastic tie wraps’ clamps should be in the position shown, lined up with each other and in a position to support the radio/FSL combination when the model is laying down flat, on a table. Cut off the excess tie wrap lengths.

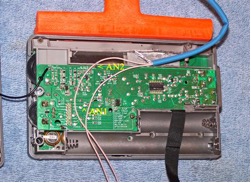

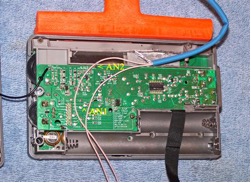

17) Refer to the photo at right. Temporarily place the Litz wires down along the radio’s circuit board in the position shown. Locate the detailed circuit board antenna connection points “AN1” and “AN2” in the close up photo at the top of the next page. After locating these two circuit board connection points (with the Litz wires running in the position shown in the photo at left) place one of the Litz wires over the “AN1” circuit board point, and the other Litz wire over the “AN2” circuit board point. Then measure out about 1” (25 mm) extra Litz wire past these two circuit board connection points, and after making sure that the Litz wires are still in the approximate position shown in the photo at the beginning of this step, cut one (shorter) Litz wire 1” (25 mm) past the “AN2” circuit board point, and one (longer) Litz wire 1” (25 mm) past the “AN1” circuit board point.

17) Refer to the photo at right. Temporarily place the Litz wires down along the radio’s circuit board in the position shown. Locate the detailed circuit board antenna connection points “AN1” and “AN2” in the close up photo at the top of the next page. After locating these two circuit board connection points (with the Litz wires running in the position shown in the photo at left) place one of the Litz wires over the “AN1” circuit board point, and the other Litz wire over the “AN2” circuit board point. Then measure out about 1” (25 mm) extra Litz wire past these two circuit board connection points, and after making sure that the Litz wires are still in the approximate position shown in the photo at the beginning of this step, cut one (shorter) Litz wire 1” (25 mm) past the “AN2” circuit board point, and one (longer) Litz wire 1” (25 mm) past the “AN1” circuit board point.

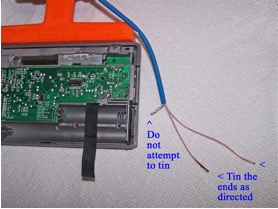

NOTE: The proper procedure of tinning the ends of the Litz wires requires that all of the individual Litz wire strands be soldered together at the ends. This requires a clean, shiny solder connection all around the circumference of the Litz wire ends for at least 1/8” (3 mm). When preparing the ends of the Litz wires in the next step, ensure that the ends are tinned in this manner before continuing.

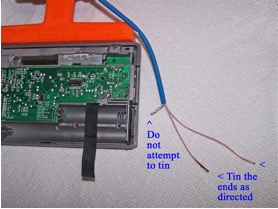

18) Refer to the photo above. Temporarily remove the Litz wires from the PL-380 cabinet and place them in the position shown, with a protective surface over your work table to avoid hot solder damage. Carefully tin the ends of both Litz wires in the manner described above, working around the circumference of the Litz wire ends with a clean soldering iron for at least 1/4” (6 mm). After doing this, cut off the tinned section on both ends to a length of 1/8” (3 mm). When viewing the ends of the Litz wires after tinning, the entire 1/8” (3 mm) length should be bright and shiny all around its circumference, as shown in the photo at the top of the next page. The cut surface of the Litz wire (the circular face) should also be bright and shiny, with one solid surface of melted solder. Do NOT attempt to tin the 1” section of aluminum foil.

19) Refer to the photo above. Position the shrink tubing as shown, with the tubing entering the PL-380 cabinet near the corner where the wrist strap was previously located. Ensure that there will be sufficient slack in the shrink tubing (as shown) to route it through the empty hole left by removal of the wrist strap without binding (after this hole is enlarged to fit the shrink tubing diameter). Take a small, flat screwdriver and carefully pry apart the cabinet clamp as shown—so that it is wide enough to grip the shrink tubing, but not so wide as to break off.

19) Refer to the photo above. Position the shrink tubing as shown, with the tubing entering the PL-380 cabinet near the corner where the wrist strap was previously located. Ensure that there will be sufficient slack in the shrink tubing (as shown) to route it through the empty hole left by removal of the wrist strap without binding (after this hole is enlarged to fit the shrink tubing diameter). Take a small, flat screwdriver and carefully pry apart the cabinet clamp as shown—so that it is wide enough to grip the shrink tubing, but not so wide as to break off.

Ensure that the circuit board points “AN1” and “AN2” still have a small amount of melted solder on them (after removal of the PL-380 stock loopstick, as described in the Loopstick transplant article). Also ensure that there is no excessive length in either of the Litz wires, since these both must be positioned as shown (if necessary, cut one or both to the proper length, and re-tin them as described in the previous step). Place the end of the shorter Litz wire (going to the AN2 circuit board point) down in a horizontal position as shown, and using a MINIMUM of heat (and no additional solder), solder the pre-tinned Litz wire end to the AN2 circuit board point while the wire is in a horizontal position. Carefully observe the connection to ensure that there are no solder bridges to the adjacent circuit board components. After ensuring this, following the detailed procedure described for the AN2 connection above, carefully solder the end of the longer Litz wire to the AN1 circuit board point in a horizontal position as shown, using a MINIMUM of heat (and no additional solder). NOTE: After soldering these connections do not attempt to force either Litz wire down in a horizontal position. Re-solder them in a horizontal position if it is necessary to get them flat against the circuit board.

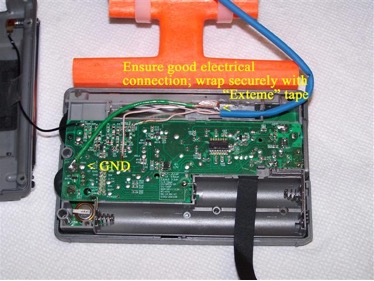

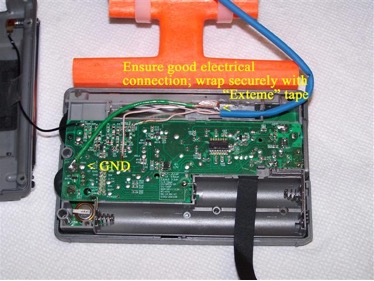

20) Refer to the photo at right. Take the 3” length of #18 hookup wire and strip off 1/4” of insulation from one end, and 3/4” of insulation from the other end. If you are using stranded wire, twist the individual strands together on each end of the wire. Tin a small amount of solder on the shorter (1/4”) bare length. Locate the “GND” marking on the circuit board as shown in the photo, and using maximum care to keep the wire as flat as possible against the circuit board, solder the tinned end of the hookup wire to the large ground connection on the circuit board immediately to the left of the GND marking. Use only a minimum of heat to make a securely soldered connection, and ensure that there are no solder bridges to adjacent areas.

20) Refer to the photo at right. Take the 3” length of #18 hookup wire and strip off 1/4” of insulation from one end, and 3/4” of insulation from the other end. If you are using stranded wire, twist the individual strands together on each end of the wire. Tin a small amount of solder on the shorter (1/4”) bare length. Locate the “GND” marking on the circuit board as shown in the photo, and using maximum care to keep the wire as flat as possible against the circuit board, solder the tinned end of the hookup wire to the large ground connection on the circuit board immediately to the left of the GND marking. Use only a minimum of heat to make a securely soldered connection, and ensure that there are no solder bridges to adjacent areas.

Cut a 3/4” x 1” section of Scotch “Extreme” tape. While holding the other end of the hookup wire next to (and making a secure electrical contact with) the 1” end of the aluminum foil coming out of the shrink tubing, slide the strip of “Extreme” tape under the connection, and securely wrap the tape around the connection (as shown) to permanently secure the two conductors together. MAKE SURE that these two conductors have a good electrical contact under the tape before continuing, since this connection is important for the model’s optimal nulling capability. During this process avoid rough treatment (or pulling) of the aluminum foil, since it is relatively fragile and easily separated.

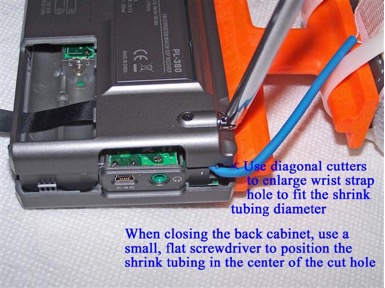

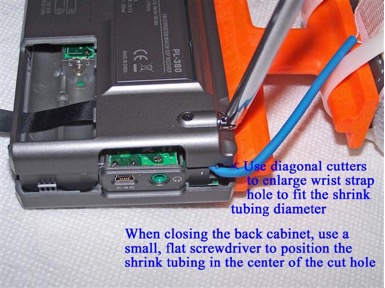

21) Refer to the photo above. Using small diagonal cutters carefully clip off small pieces of the back cabinet’s wrist strap hole so that it will be of a similar size to that of the shrink tubing, in order to run the shrink tubing through without any pinching or damage. Ensure that the cut pieces do not fall inside the PL-380 cabinet.

21) Refer to the photo above. Using small diagonal cutters carefully clip off small pieces of the back cabinet’s wrist strap hole so that it will be of a similar size to that of the shrink tubing, in order to run the shrink tubing through without any pinching or damage. Ensure that the cut pieces do not fall inside the PL-380 cabinet.

Take the PL-380’s back cabinet section and carefully bring it close to the radio, as shown in the photo. Ensure that the whip antenna’s lead-in wire is not pinched, and also ensure that the shrink tubing is routed is a position close to the empty wrist strap hole in the back cabinet, as shown. As a first step, carefully mate the radio’s back cabinet to the radio’s right side (the one opposite the wrist strap hole) while continuing to guide the shrink tubing through the wrist strap hole. Finally, using a small, flat screwdriver, center the shrink tubing in the center of the wrist strap hole while mating the remaining (left) side of the cabinets together. Ensure that the shrink tubing is not pinched or extremely tight as it is clamped down in this hole. While holding the two cabinet sides together move the whip antenna up and away from the cabinet screw hole underneath, and insert the first cabinet screw, tightening it temporarily to keep the shrink tubing in position. Then insert and tighten the left upper and left lower cabinet screws thoroughly, while snapping the right lower cabinet sections together. Finally, after ensuring that the shrink tubing is still in the center of the wrist strap hole without any binding or excessive stress, tighten the final cabinet screw near the whip antenna base. Reinstall the two small battery compartment screws and reinsert batteries. This completes the assembly of the 4.25” FSL Tecsun PL-380 model.

Initial Testing

If you are not familiar with the PL-380, make sure that you study the owner’s manual to find the location of basic operating controls. It is important to initially test the radio in a location free of computer noise or other RF pollution—preferably in an outdoor location where its capabilities can be appreciated. Refer to the photo on the next page. Turn on the radio and select the Medium Wave band (530-1700 kHz in North America) and set the AM bandwidth control to the most selective (1 kHz) position (NOTE: This position also provides maximum MW and LW sensitivity for the model, although the higher audio frequencies are limited somewhat by the sharp DSP filtering). If your FSL antenna transplant is working properly you should notice an EXCEPTIONAL increase in the signal strength of weak fringe stations relative to the stock PL-380 model, and a very significant increase in fringe station strength relative to a 7.5” loopstick PL-380 model. Check fringe station strength across the band, and you should notice MW reception far superior to that of any stock portable in your collection. If you are not receiving any MW signals the problem is usually easy to trace—either one of the PL-380 circuit board connections is shorted to adjacent components because of too much solder, or the physical stress on the Litz wires (because they were not soldered in a horizontal position) has caused the circuit board connections to break off and separate from the board. In the first case you can attempt to remove excess solder by turning the circuit board upside down and melting the excess solder onto the tip of your soldering iron (or using a “solder sucker” in a normal position), but in the second case you will probably need a technician to restore proper function to your radio. Fortunately both of these problems are rare, and can be entirely avoided by carefully following the instructions in Step19.

Operation

The triple advantage of superior FSL sensitivity, sharp DSP selectivity and exceptional nulling capability provide this breakthrough model with unprecedented weak-signal performance for a portable—to the extent that after a few DXing sessions the operator may have the impression that the realm of science fiction has been approached.

During DXing sessions it is a good idea to support both the PL-380 and FSL antenna frame in the same hand (as shown in the photo above), and also to avoid sudden mechanical stress or bumps to the antenna frame. When constructed according to this article the glue bond between the antenna frame and PL-380 is sufficient for routine operations, but the DXer should exercise care to avoid bumps, drops or other stress. The FSL antenna itself is fairly rugged, as constructed.

Refer to the photo above. The PL-380 has many digital search functions and advanced capabilities for a pocket radio, but some of the functions of particular interest to the transoceanic DXer are described here. The “AM Bandwidth” switch allows you to choose different levels of DSP filtering to limit splatter from domestic pests, and is usually left in the 1 kHz position for the narrowest filtering while chasing transoceanic DX (although this position does cut off some of the high frequency audio from the desired DX station). The 9/10 kHz switch allows you to change the tuning steps of the radio from the North American (10 kHz) band system to those of the European/ African/ Asian/ Pacific band system (9 kHz), depending upon your preferred DX targets. The MW / LW switch allows you to switch over to Longwave DXing—and you will be pleasantly surprised to discover that your newly installed 4.25” Bar FSL antenna is FAR more sensitive on the Longwave band than the stock PL-380 loopstick. Finally, the Display switch offers you multiple options while chasing transoceanic DX—you can have a 24 hour clock display, a display of the alarm time set in the radio, a constantly changing readout of DX signal strength and S/N ratio, or a temperature display (in either Celsius or Fahrenheit).

Because the antenna frame has been trimmed to allow full operation of the PL-380’s whip antenna to receive SW and FM signals, it’s possible to check the Shortwave parallels of Medium Wave DX stations (and switch back and forth) within a couple of seconds. In general, this “science fiction” PL-380 model’s sensitivity, selectivity and nulling capability will allow you to experience the most exciting AM-DXing fun that a portable can offer—and do so at an unbeatable price.

Nulling Pest Stations

This modified PL-380 was specifically designed to have unprecedented nulling capability for a portable, and when assembled according to the instructions it is capable of razor-sharp nulls on most semi-local and even local MW broadcast stations. Using the nulling function to maximum advantage takes a little bit of practice, and an understanding of the importance of both a horizontal and vertical null angle for different pest stations. It also helps to be in a clean RF environment, away from computer noise, AC house wiring and other limiting factors.

The horizontal null angle is pretty easy to determine—simply point the side of the FSL antenna toward the pest station’s direction until a minimum signal bearing is found. If you have an extremely powerful pest station that makes this impossible to determine on the fundamental frequency, detune the radio (off the pest station’s frequency) by about 10 kHz and try to find the bearing with the minimum pest station splatter .

Once you determine the horizontal null bearing, hold the radio at that bearing and carefully tilt the radio up and down at a slightly vertical angle to determine the absolute minimum signal point. This will be different for each pest station, so it is helpful to write these vertical null bearings down once you determine them, and memorize them if possible. They can be either positive angles (with the radio tilted upward) or negative angles (with the radio tilted downward). The point where the vertical null bearing intersects with the horizontal null bearing will always be the direction of the absolute minimum signal—you can picture this as two lines intersecting at a single point in space. Once the side of the FSL antenna is directed at that point, the signal of most pest stations will disappear into the noise. Since this point can be razor-sharp, it is often helpful to support one side of the radio on a “Lazy Susan” type assembly to keep the radio directed at the horizontal null bearing while you are finding the vertical null bearing.

The closer you are located to a pest station the tougher it will become to null it down into the noise—although this particular model will give you the best possible chance of success. Of course if you are located right next door to a 50 kW pest, you will probably need a little more “science fiction” than this model can provide J

This hard-wired FSL-enhanced PL-380 model is the second in a series of portables designed to be the ultimate “travel radios,” with DXing potential superior to any stock design. It has been a great thrill to design, construct and introduce these models, which are pretty fanatical in both appearance and DXing capabilities. My hope is that their function will inspire those who build and use them, and help them share my impression that the MW-DXing hobby has a very innovative and exciting future!

73 and Good DX,

Gary DeBock

Gary, again, thank you for documenting this procedure so thoroughly! No doubt, many a mediumwave DXer can benefit from the excellent nulling characteristics of your “Pest Control” FSL antenna!

Click here to view other tutorials and articles by Gary DeBock.